HOW OUR SAILS ARE MADE

HOW OUR SAILS ARE MADE

From digital modeling to final finishing, North Sails integrates design, engineering, and expert craftsmanship into a seamless process that creates the world’s best sails.

North Sails is the most advanced sailmaker in the world, known for changing the game through breakthrough materials and innovative manufacturing methods such as true 3D‑shaped sails. Our ambition is simple but uncompromising: to design and deliver the best sailing experience on the planet, and superior value for every sailor. With the most talented people, cutting‑edge technology, and decades of hard‑won experience built into every product, North sails are engineered to perform at the highest level.

That performance begins with how our sails are made. North Sails employs industrial designers and expert sailmakers who develop the most advanced, vertically integrated manufacturing processes in the industry. All sails are produced in North‑owned facilities worldwide, following rigorous standards that reflect our investment in R&D, quality control, and global knowledge sharing. The same passion, pride, and precision go into every sail, whether it is built for Grand Prix racing or for relaxed cruising. The technical expertise gained from working with championship‑winning teams is embedded in every design, ensuring that every North sail, regardless of size or purpose, is made to be the best, by the best.

WHERE EVERY SAIL BEGINS

THE DESIGN PROCESS

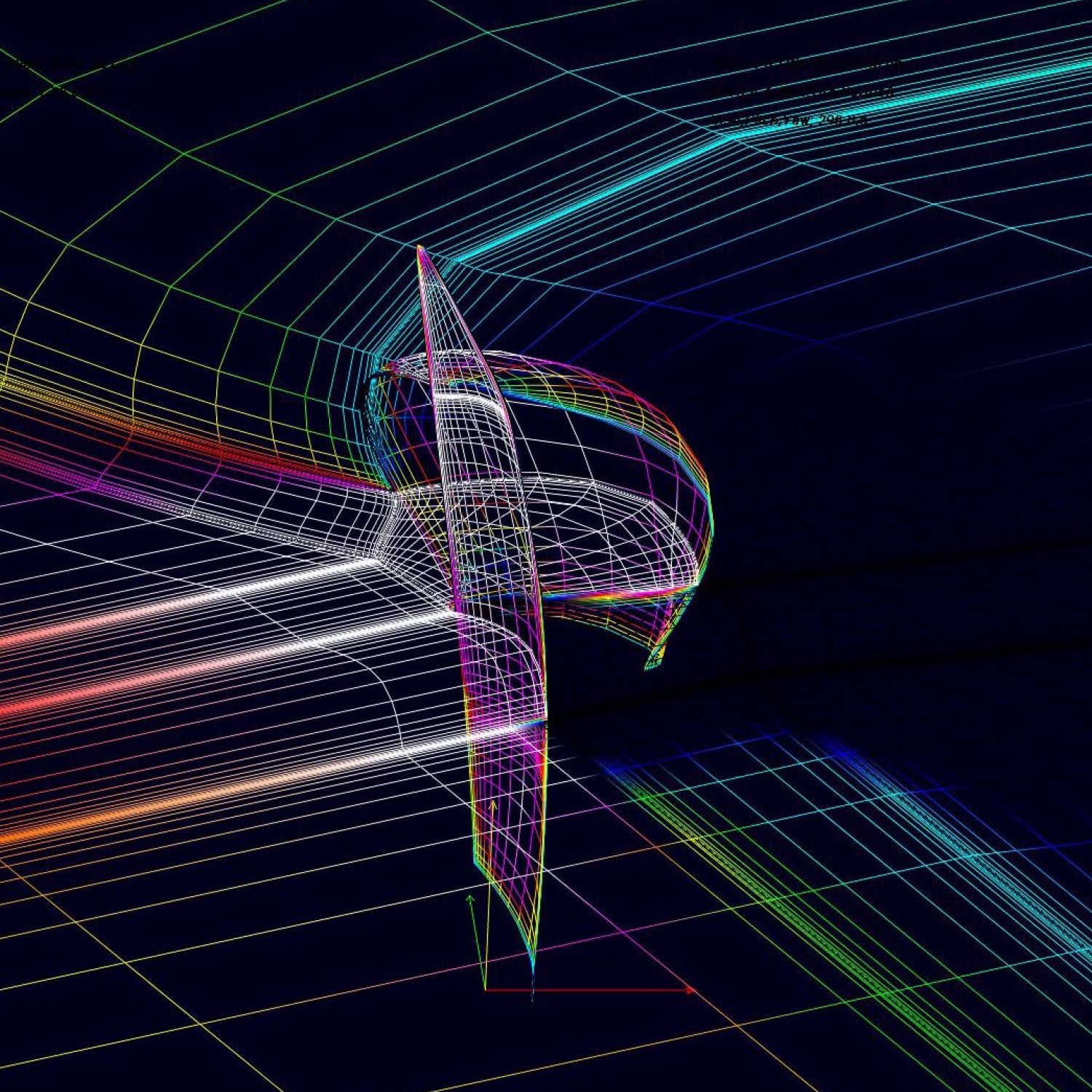

Every sail we build starts in the North Design Suite. While there are established standards for creating a fast, efficient sail, true performance comes from refining every detail and integrating the sail precisely with the boat it will power. Our design suite is unique in that all the software is developed in-house. This allows unparalleled accuracy, flexibility, and constant evolution as materials, sailing styles, and performance demands change.

The design engineers begin by understanding the full operating environment and intended use of the sail – expected wind ranges, boat speed, rig and mast characteristics, and how much load the boat can safely handle. Using advanced simulation tools, the team virtually applies real-world forces to the sail, predicting how it will perform when set, adjusted, and loaded on the water.

Sail design uniquely demands mastery of both aerodynamics and hydrodynamics – how air flows over the sail to generate drive, and how the boat and keel interact with the water to convert that drive into speed and stability. Unlike most performance industries, both forces must be modeled together, as changes to one directly affect the other. That’s why North sail designers are not only engineers, but also highly experienced sailors who understand how theory translates into performance.

Every sail we build starts in the North Design Suite. While there are established standards for creating a fast, efficient sail, true performance comes from refining every detail and integrating the sail precisely with the boat it will power. Our design suite is unique in that all the software is developed in-house. This allows unparalleled accuracy, flexibility, and constant evolution as materials, sailing styles, and performance demands change.

The design engineers begin by understanding the full operating environment and intended use of the sail – expected wind ranges, boat speed, rig and mast characteristics, and how much load the boat can safely handle. Using advanced simulation tools, the team virtually applies real-world forces to the sail, predicting how it will perform when set, adjusted, and loaded on the water.

Sail design uniquely demands mastery of both aerodynamics and hydrodynamics – how air flows over the sail to generate drive, and how the boat and keel interact with the water to convert that drive into speed and stability. Unlike most performance industries, both forces must be modeled together, as changes to one directly affect the other. That’s why North sail designers are not only engineers, but also highly experienced sailors who understand how theory translates into performance.

THREE CRITICAL ELEMENTS OF SAIL DESIGN

Every sail design integrates three elements: geometry, shape, and structure. Once the geometry of the sail is established, shape and structure are inseparable – without structure, shape is unstable, and without shape, structure delivers no drive.

GEOMETRY

Ensuring the sails fit the boat perfectly, with all attachment points precisely positioned.

SHAPE

Defining the aerodynamic form of the sails to achieve desired performance.

STRUCTURE

Engineering the internal load paths to suit the intended use and sailing conditions.

TWO SAIL CONSTRUCTION METHODS

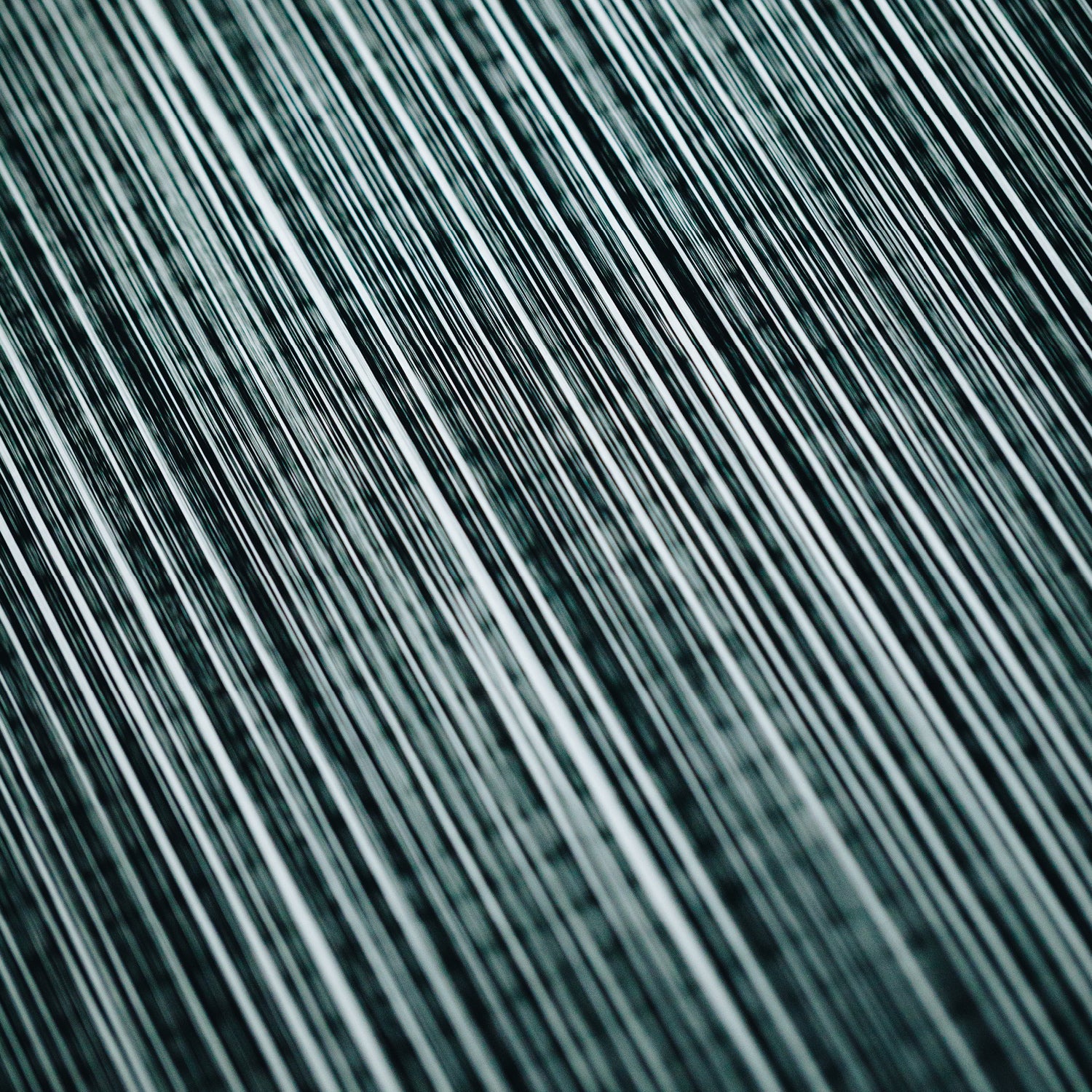

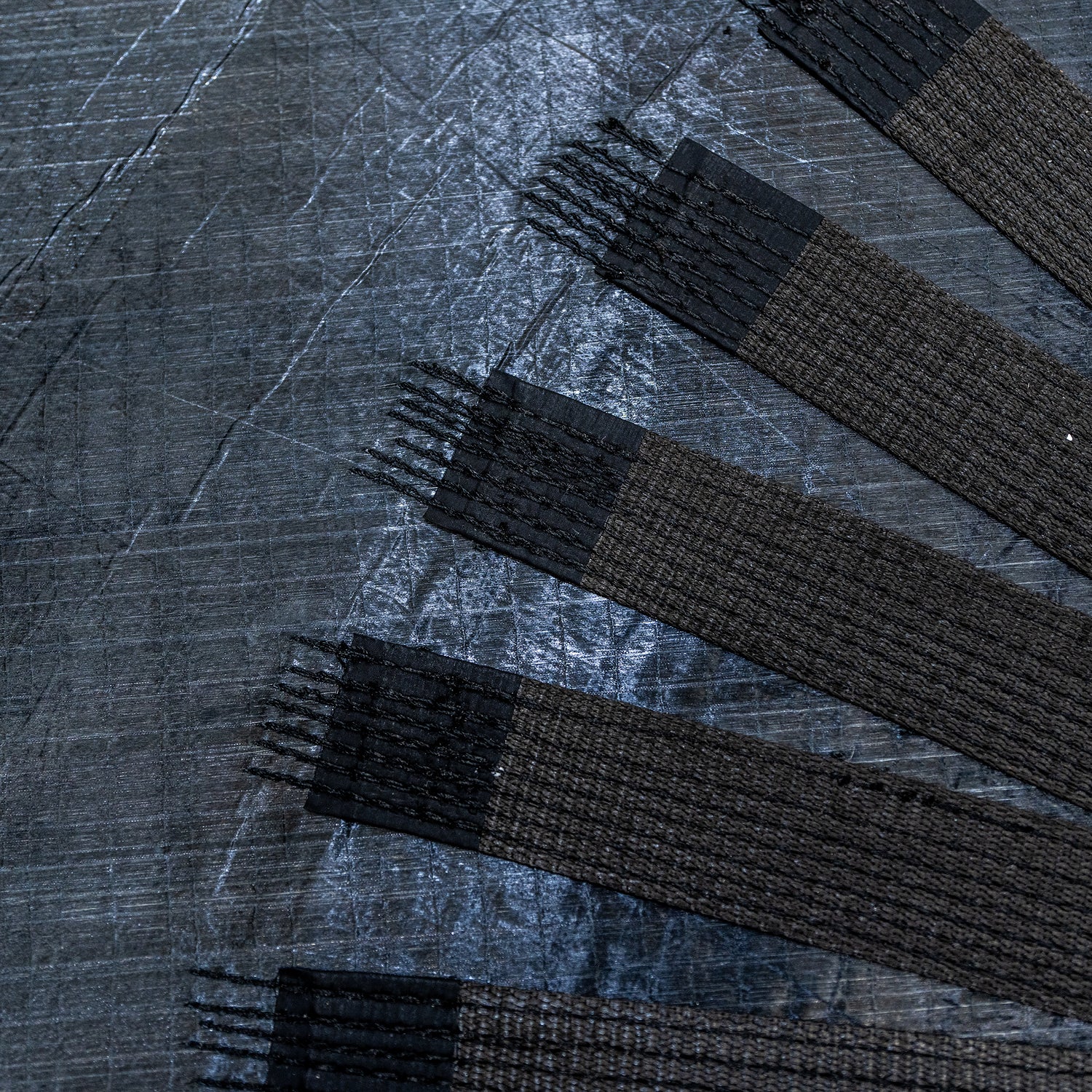

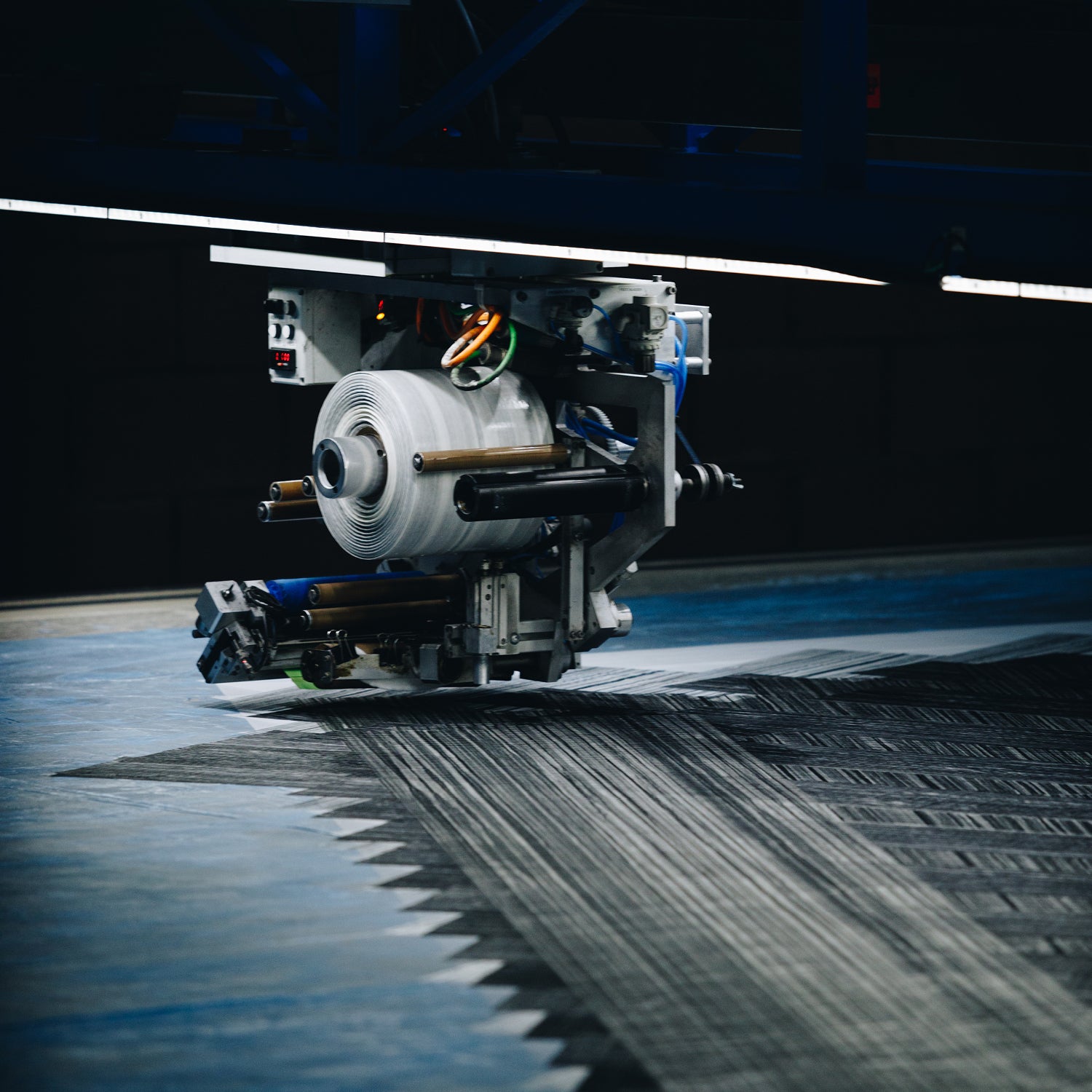

North builds sails using two distinct construction methods – Paneled and 3Di Molded – each designed to deliver smooth, fast, and efficient performance for every type of sailor. Whether you’re cruising on a 30‑footer or pushing a super maxi, both construction styles offer reliable power; the best choice simply depends on how and where you sail.

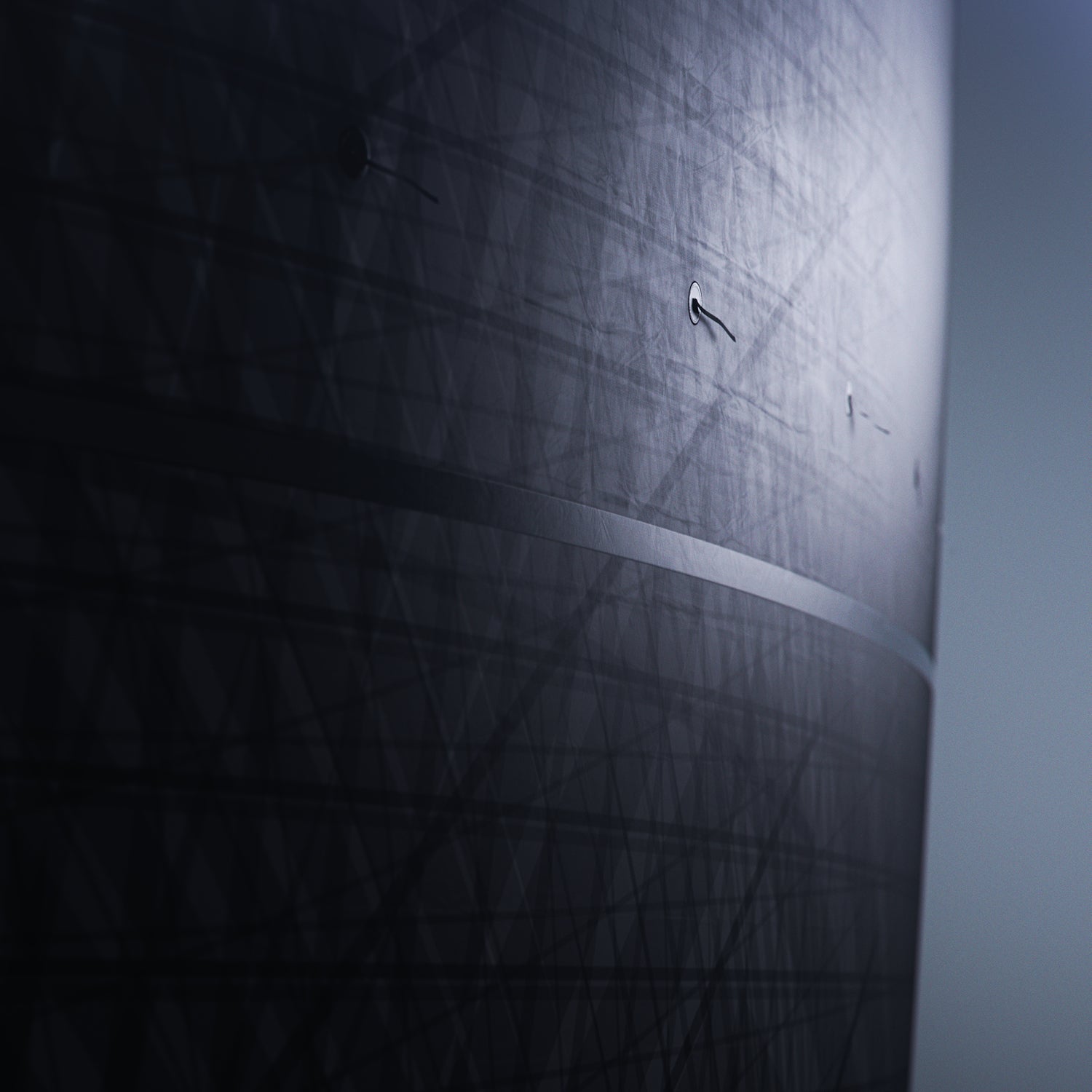

FINISHING AND QUALITY CHECK

Once a sail’s structure and shape are complete, it enters one of the most critical phases of its journey: finishing and quality control. Regardless of whether it’s a paneled or a 3Di sail, each sail is fully laid out, measured in every dimension, and checked against the original design specifications to ensure it will fit the boat exactly as intended. Edges are trimmed and faired, curves refined, and all perimeter details carefully finished. Hardware, batten pockets, corner reinforcements, luff systems, and load-bearing attachments are added or completed with meticulous attention to alignment and strength. Experienced sailmakers inspect stitching, bonds, and the sailcloth, correcting even the smallest imperfections. Only once the sail meets North Sails’s rigorous standards – functionally, structurally, and visually – is it approved to leave the loft, packaged and shipped to their destination.

It’s a final, uncompromising check that ensures every sail delivered is not just engineered to perform, but finished to last.

BUILT WITH PURPOSE BACKED BY EXPERTS

Choosing the right sail starts with understanding how you sail. Our loft teams work closely with sailors around the world to translate design and technology into real‑world performance. Contact your local North Sails loft or request a quote to start the conversation.

Choosing the right sail starts with understanding how you sail. Our loft teams work closely with sailors around the world to translate design and technology into real‑world performance. Contact your local North Sails loft or request a quote to start the conversation.

START YOUR JOURNEY TODAY

LATEST NORTH SAILS NEWS

15 February

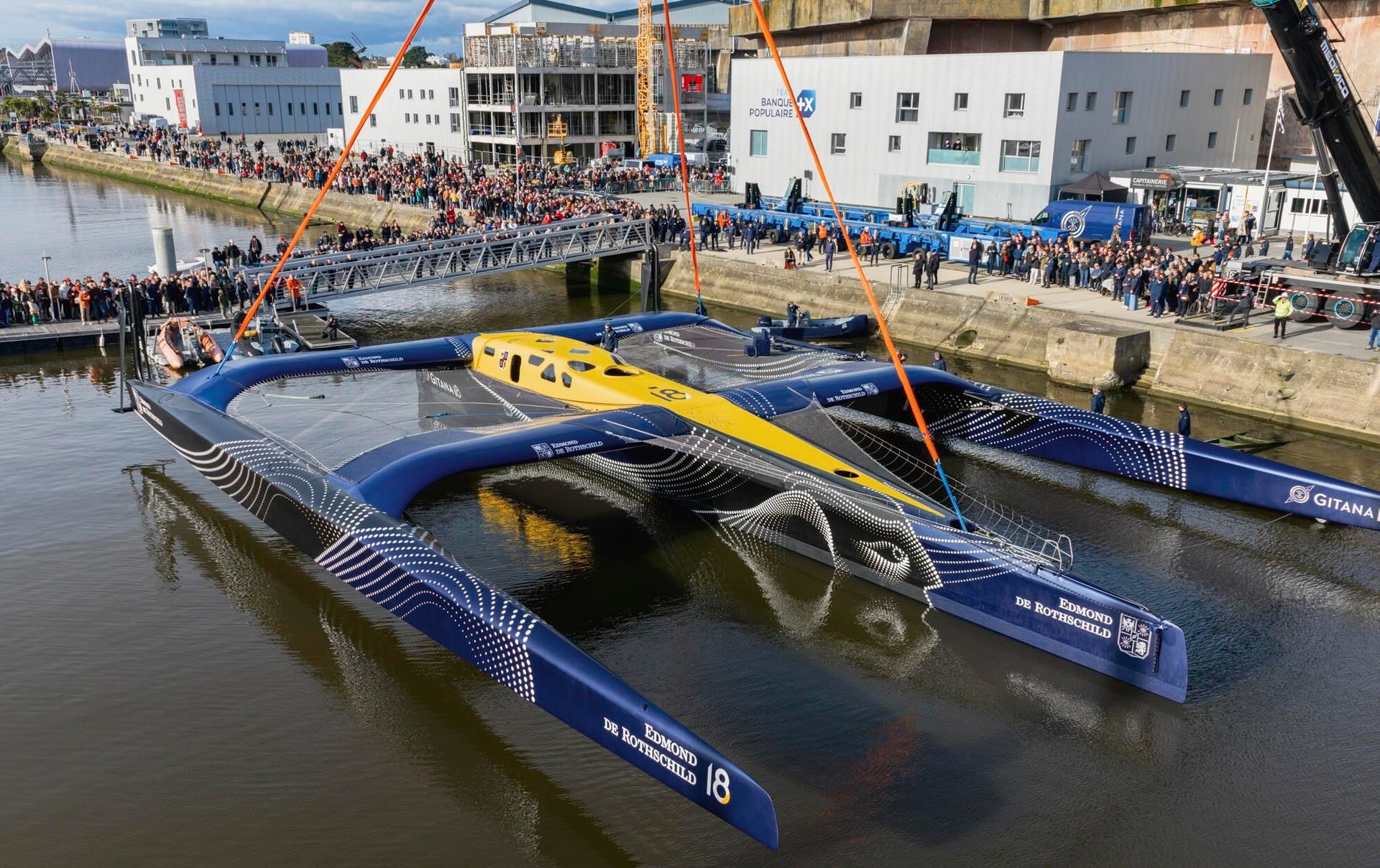

GITANA 18 LAUNCHES A NEW CHAPTER

13 January