CHAFE NEVER SLEEPS

CHAFE NEVER SLEEPS

Our DIY Sail Care information only applies to traditional fabrics and laminates. 3Di is composite technology, not a sail laminate. For info on 3Di sail care, read Sail Maintenance. Here is what you need to know about chafe on traditional fabrics.

North Sails CEO Dan Neri shows us how to keep chafe from destroying your sails.

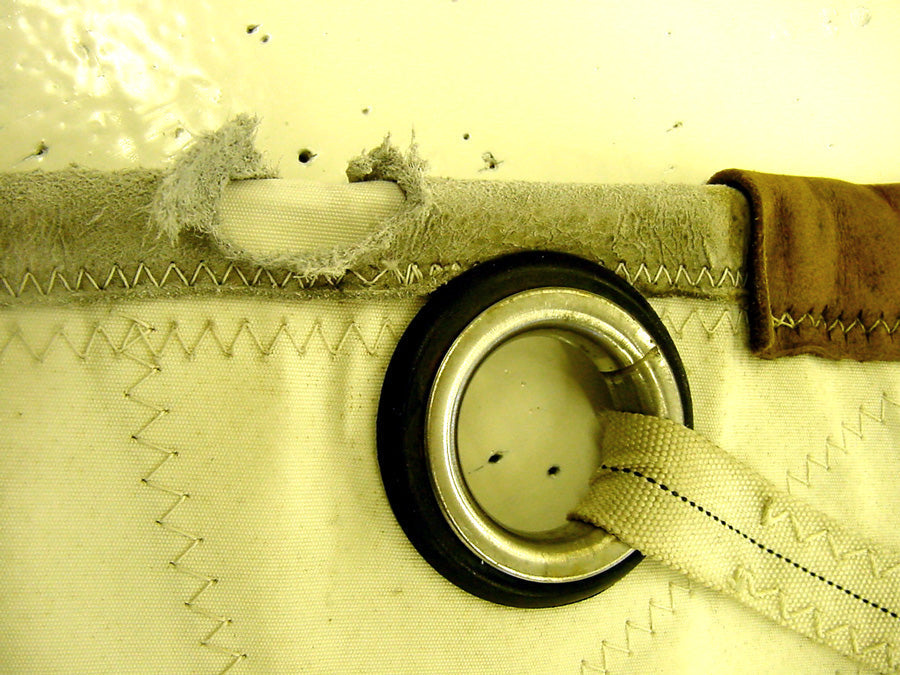

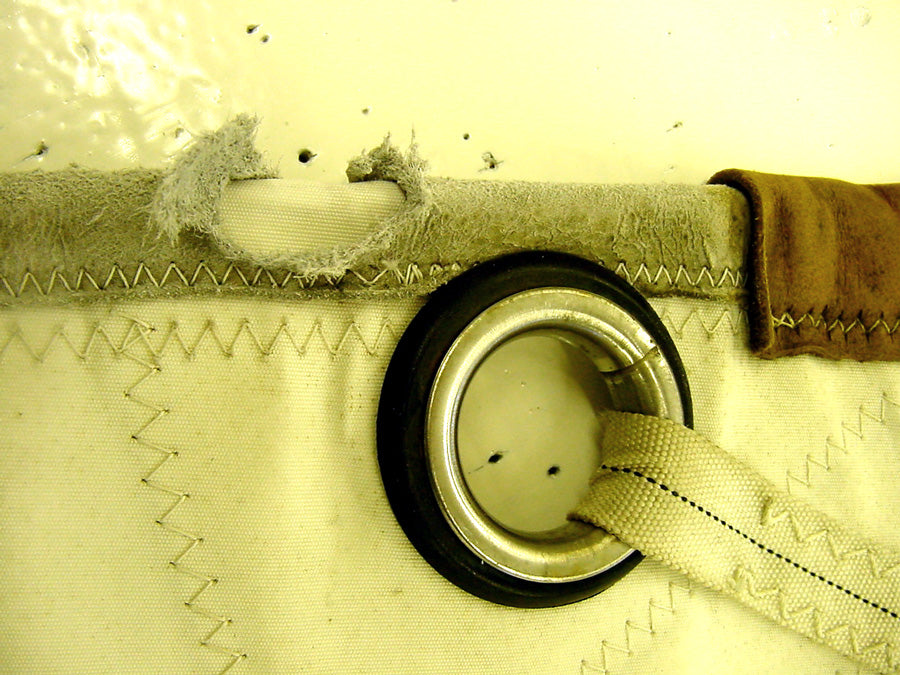

Wherever soft, fabric parts of a sail rub against hard metal parts, the sail is going to eventually suffer chafe damage. It is difficult for a sailmaker to identify all potential chafe areas, so you must watch for chafe and add (or replace) chafe protection before a hole appears.

Heavy dacron and webbing work best for chafing surfaces around rings. Webbing is easy to fold around corners and is made of thicker fibers, so it will wear better than Dacron. Dacron, on the other hand, is easier to sew due to its lower bulk. We are not particularly fond of leather for chafe protection, even though it looks nice when it is new. Leather stretches when it is wet, so it is more easily ripped than webbing chafe guards.

Anytime you see your sail rubbing on the rig, or see a lazy jack or running stay rubbing on the sail, circle the area of contact with a marking pen. Then, at your first opportunity, cover the area that you have marked with an appropriate material.

How to make chafe patches

The most common chafe material is “Stickyback.” Due to its lightweight it will conform to the surface of the sail, even if it is applied over areas that include staggered layers of reinforcing, or batten pockets. The surface is slippery, which allows the fabric to slide against other materials without grabbing or heating up from friction. However, because it is thin and made from lightweight fibers, this is really only a temporary solution.

Heavier weight chafe patches can be made from woven polyester sailcloth and several strips of seamstick adhesive, or a thin layer of liquid adhesive. Whenever possible, chafe material should be applied with adhesive rather than sewing because it will need to be renewed at some point. Stitching will leave holes in the sail when the old chafe material is removed, and more holes when the replacement material is installed. Multiple layers of lighter weight material installed with adhesives are the best way to go.

For multiple layer patches, the large layer should be 20-40% bigger than the small layer to taper the patch.

Common chafe areas include:

Spreaders

Where spreader ends push hard into the surface of a sail, you need a sewed-on dacron patch on each side of the sail. If the sail leech scrapes across the spreader base during tacks, but does not come into contact with the spreader end, use a lighter, completely sacrificial patch.

Mainsails on boats with swept back spreaders are prone to punctures from the spreader ends both when sailing downwind and while reefing. As mainsail loads change, the fabric is pressed hard against the spreader end. Eventually, the spreader end chafes a hole in the sail. Because the hole is on the leeward side, you may not see it.This can result in significant damage if not addressed right away.

Tips to minimize sail damage when reefing

- Slightly over trim the sail or keep tension on the boom vang.

- Monitor the chafe protection layers on the sail.

- Wrap the spreader end with black tape so the spreader will make a mark on the sail as an early warning sign.

Stanchions

If the foot of the headsail sometimes catches on a stanchion top, sew a dacron patch on each side of the sail. If the foot of the sail sometimes rubs on the shackle that attaches the upper lifeline to the bow pulpit, add a lighter, completely sacrificial patch.

Full-length batten pockets

Full-length battens rub on standing rigging, running backstays, and lazy jacks. Standing rigging is the biggest concern because it is rigid. The batten is also rigid, so the pocket material is in between the proverbial rock and the hard place. Pockets should be covered with a rugged layer of fabric or webbing, preferably spectra because it does not heat up from friction like polyester. Nylon webbing has good chafe resistance, but it shrinks and will cause the batten pocket to pucker.

How to make a batten pocket chafe guard

- Cut a piece of light sailcloth tape so it is the same length and width as the batten pocket.

- Stitch spectra webbing along its center.

- Glue the tape to the pocket with the spectra facing out.

- Stitch along the edges of the batten pocket, matching the existing machine stitching as much as possible.

Excerpted from The Complete Guide to Sail Care and Repair, by Dan Neri