1987 - NORTH SAILS DESIGN SUITE EXPANDS WITH FLOW™ AND MEMBRAIN™

North Sails Design Suite Software Expands with Flow™ and Membrain™

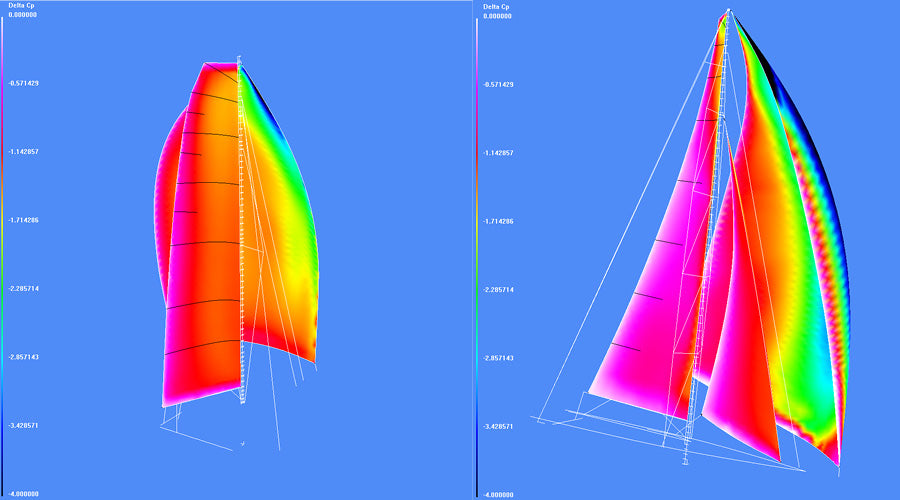

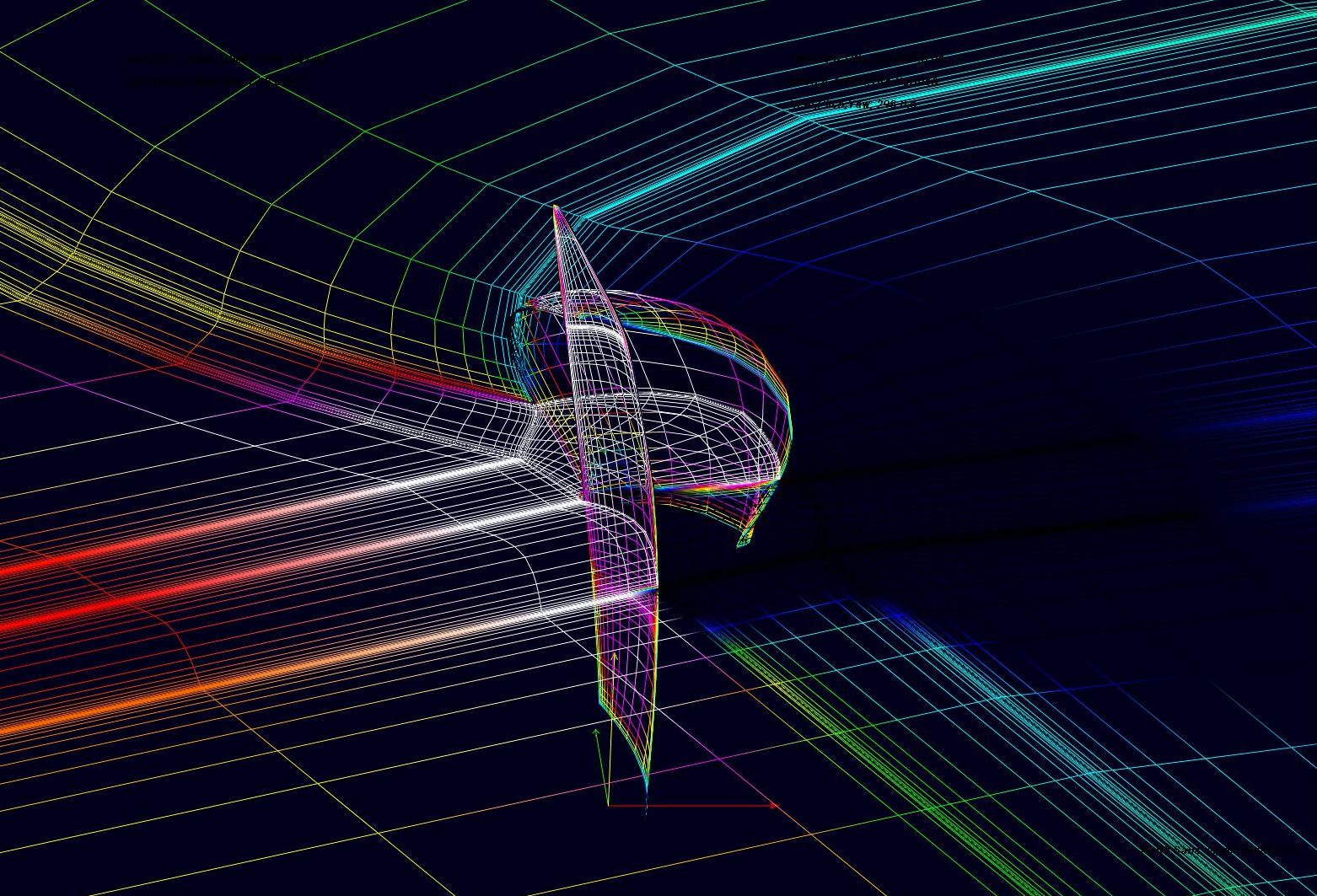

Among the tools most commonly used by North Sails designers are the Membrain and Flow modules, which apply wind pressure to a sail’s surface and calculate the load forces created. Designers pressurize their sail shapes virtually to discover what their flying shape will be in the intended range. Flow and Membrain work in tandem with the sail shape moving back and forth between them. Designers first analyze the structure in Membrain and continue by applying pressure to see how the shape deforms when pressure is applied in Flow. They continue this feedback “loop” of testing and correcting until they are happy with both the sails’ structural integrity and flying shape.

Take a shallow dive into the technical and often intriguing world of Membrain and Flow with the screen captures below. Begin to understand the many ways design horsepower keeps North Sails at the forefront of sailing technology.