NORTH SAILS BLOG

Alle

Events

Guides

News

People

Podcast

Sustainability

Tech & Innovation

Travel & Adventure

FIVE SAIL PREP TIPS

FIVE SAIL PREP TIPS

Here are some easy things you can do on your own to make sure your sails are ready for the season.

1. MAINSAIL

Inspect the luff of the sail to see if the luff slides, or the boltrope, require attention. Make sure to look for loose or missing slides, chafing through the boltrope cover.

2. MAINSAIL

Inspect the batten pockets, both ends, to make sure that the battens will be secure, tight and doing their job. Velco can wear out over time and may need to be replaced.

3. FURLING GENOA

Inspect the UV cover to see if it has any loose stitching or fabric that has been fatigued by the sun. Most UV covers require some maintenance every two years.

4. RACE GENOA

Inspect around the spreader patches looking for impact and abrasion damage. Pay particular attention along the full length of the foot and leech - this is where sails take the most abuse.

5. JIBS w. BATTENS

Inspect the battens pockets looking for fatigue and wear at both ends of the pockets.

If you find anything that needs attention - Better Call Joel!

READ MORE

READ MORE

WHO WE ARE: DOMICIANO MANGUBAT

WHO WE ARE : DOMICIANO (KID) MANGUBAT

Get to know your local service expert

Domiciano, or as many know him Kid, Mangubat has been with North Sails for many years. His experience in the industry is unparalleled and speaks for itself with every sail he touches. He has been with the Toronto loft since he started with North Sails.

How long have you been working with North Sails?

I've been on the North Sails team for nearly 33 years now. I joined the team in January of 1985.

How did you get involved in the sailmaking industry?

I was 17 years old when I first came to Toronto. I was looking for work and was fortunate enough to have a friend of my sister offer me a job in the sailmaking industry. Since then I have trained with respected veteran sailmakers such as Hans Fogh, Steve C and Mark. They all taught me how to make a variety of different sails; anywhere from small dinghy sails to mega yacht sails. Since then, I knew this would be the job for me.

What do you enjoy about sailmaking?

Each day is a different day and each sail is different, so I enjoy the challenged that come along with sailmaking. I would describe myself as a handyman so building sails is a lot of fun for me. On top of sailmaking, I enjoy the opportunity that comes along with it such as travelling. During my here with North Sails, I've gone to places like Sri Lanka and places all over the United States.

Everyday is a new opportunity to learn something new. I know how sailmaking allows me to connect with customers in terms of their needs, whether it's cruising or racing.

What’s your best advice for sailors when it comes to sail care?

My best advice when it comes to sail care is:

Inspect your sail regularly and have an expert do so

Keep your sail clean and bag it

Learn more about the North Sails Toronto team, see here.

READ MORE

READ MORE

MELGES 24 EUROPEAN SAILING SERIES, ALTEA BRILLA A PUNTA ALA

MELGES 24 EUROPEAN SAILING SERIES, ALTEA BRILLA A PUNTA ALA

© zerogradinord

Punta Ala – Cala il sipario sulla prima tappa del circuito internazionale Melges 24 European Sailing Series, organizzato da International Melges 24 Class Association con il supporto logistico, per la prima frazione, dello Yacht Club Punta Ala.

Condizioni meteo variabili e vento irregolare hanno comunque consentito al Comitato di Regata presieduto da Alessandro Testa di portare a termine una serie completa di nove regate, tre per ciascuna giornata: non poteva sperare in meglio la flotta di quindici Melges 24 scesa in acqua a Punta Ala dopo la lunga pausa invernale.

A brillare dopo un lungo testa a testa con gli Ungheresi di FGF Sailing Team è stato Andrea Racchelli con la sua Altea che, dopo nove anni e al primo ritorno della flotta Melges 24 in quel di Punta Ala, ha replicato il successo ottenuto nel 2009 oggi come allora utilizzando profili North Sails.

Più in generale, l’evento si è rivelato un grande successo per North Sails, che ha piazzato sette barche nella top ten di questa manifestazione che ha aperto ufficialmente la stagione del più longevo tra i one design prodotti dalla Melges Performance Sailboats.

Per la classifica finale dopo nove prove e uno scarto clicca qui.

READ MORE

READ MORE

Consejo North Sails

CONSEJO NORTH SAILS

Hoy hablamos del Código 0. Si a bordo de nuestro barco disponemos de Código 0, recomendamos combinarlo con una driza de Dyneema.

© Alex McKinnon

Si disponemos de enrollador top-down (que, como su nombre indica, enrolla desde driza hasta amura), aunque no lo utilicemos en regata, es importante una buena driza de Dyneema; esto evita que el cabo gire sobre sí mismo y estire. Para enrolladores bottom-up (enrolla desde amura hasta driza), la combinación más recomendable es disponer de un buen cabo antitorsión y driza de Dyneema. Por norma general, si además de navegación en crucero queremos realizar alguna regata, un buen consejo es equipar todas las drizas de Dyneema. Su menor estiramiento facilita el trimado de las velas y hace que no tengamos que ajustarlas constantemente.

READ MORE

READ MORE

VOR: COMIENZA LA ETAPA REINA

VOR: COMIENZA LA ETAPA REINA

La flota Volvo Ocean Race partió el pasado domingo de Auckland (Nueva Zelanda) rumbo a Itajaí (Brasil) para disputar la séptima etapa de esta edición 2017-18.

© Ugo Fonolla - Volvo Ocean Race

Considerada la etapa reina del recorrido, transcurre a lo largo de 7.600 millas náuticas por el Océano Sur y el Océano Atlántico, e incluye el paso por el temido Cabo de Hornos, en el extremo Sur del continente americano. Cada Volvo Ocean 65 afronta la travesía con un inventario de ocho velas North Sails 3Di (más tormentín). North Sails es la velería oficial de la Volvo Ocean Race 2017-18.

READ MORE

READ MORE

MASTER CLASS EN SANXENXO

MASTER CLASS EN SANXENXO...

El Real Club Náutico de Sanxenxo acogió los días 16 y 17 de marzo una Master Class North Sails para los participantes de la 4ª Regata Interclubes Ría de Pontevedra, la tercera consecutiva dentro del programa de la prueba pontevedresa.

© Desmarque

En esta ocasión, corrió por cuenta de nuestros expertos Jorge Martínez Doreste, Marc Patiño y Fernando Pazó, que hablaron sobre el catálogo de velas North Sails e impartieron nociones sobre trimado en ceñida. Durante la segunda jornada, nuestro equipo salió al agua a grabar y fotografiar a la flota para posteriormente debatir con los regatistas cómo mejorar su experiencia de navegación.

READ MORE

READ MORE

NORTH DESIGN SUITE: CIENCIA APLICADA AL DISEÑO

NORTH DESIGN SUITE:

CIENCIA APLICADA AL DISEÑO

North Sails ha desarrollado una potente herramienta para optimizar el diseño de sus velas: el North Design Suite, una familia integrada de programas especializados que permiten analizar todos los parámetros de las velas antes de ser fabricadas. Juan Garay y Juan Meseguer, integrantes del equipo de diseñadores de velas North Sails, nos explican en qué consiste.

© North Sails

Juan Meseguer y Juan Garay llevan una década en las mejores escuadras de competición del mundo. Hoy, ambos se encuentran inmersos en la súper profesional clase TP52, considerada la vanguardia del I+D en monocascos de competición, y que está sirviendo como campo de ensayos y plataforma de entrenamiento para potenciales equipos de la próxima America’s Cup. Mucho de ese desarrollo se realiza utilizando el North Design Suite, la herramienta de diseño más potente y versátil de la industria velera, que ayuda a los diseñadores a crear velas a medida y optimizadas al máximo.

“Todo pasa por el North Design Suite, lo utilizamos a diario”, explica Garay. “Somos buenos diseñadores, pero en gran parte es gracias al software”. Y aunque la alta competición es el campo de ensayos para esta evolución tecnológica, los avances no se quedan en el campo de regatas. “El resultado de este trabajo repercute en todas las velas que diseña North. Tenemos herramientas para conseguir que cualquier barco navegue más rápido y podemos ayudar a los tripulantes a optimizar el trimado y puesta a punto de las velas. Todo ello es posible utilizando el North Design Suite”.

Software especializado

La magia del North Design Suite es posible gracias a la combinación de sus 13 módulos de software especializados. Cada uno de ellos está desarrollado específicamente para una función y puede interactuar con otros módulos.

“Aplicamos tecnología de última generación para ayudar en la toma de decisiones”, explica JB Braun, jefe de diseño e ingeniería en North Sails. “La herramienta VPP (o Velocity Prediction Program, que predice las prestaciones del barco con especial atención a las formas de las velas) nos permite organizar todos los parámetros de las prestaciones del barco en un modelo: Cómo diseñamos la vela, qué velas combinamos para lograr las mejores prestaciones, qué impacto tienen los diferentes diseños en la velocidad del barco,...”.

Gracias al North Design Suite, los diseñadores ahorran tiempo y consiguen diseños más precisos.

“Eliminamos un nivel de incertidumbre que no sería posible conseguir sin esta herramienta”, indica Garay. “Realizamos pruebas para analizar la causa y el efecto de diferentes variables. La herramienta reduce el proceso de experimentación y conjeturas de los programas de test tradicionales y proporciona mejor información para conseguir diseños más precisos antes de que el barco toque el agua”.

Juan Meseguer coincide en la importancia del software para mantener el estatus de North Sails como líder indiscutible del mercado.

“El North Design Suite es exclusivo de nuestra compañía, y nos permite ofrecer velas más específicas al tiempo que limita la cantidad de velas de pruebas que un programa deportivo tiene que comprar”.

Para más información sobre las velas North Sails, visita www.northsails.com o contacta con nosotros en info@es.northsails.com

READ MORE

READ MORE

MEASURED & READY TO GO

MEASURED & READY TO GO

Local North Sails sales experts get racers measured & certified for the upcoming racing season

Racers gathered at our Toronto loft this past weekend to prepare for the upcoming season by getting their sails measured & certified. Our sales experts, Hugh Beaton and Mike Wolfs, and service team, Joel Caro, were on hand answering questions & providing service advice for sails brought in.

Our team of experts walked sailors through the measurement process, what would be involved in servicing them including a brief overview of our 10 Point Inspection and recommendations for improving sail handling. LOOR Chair Joe Doris stopped by with his Genoa for his Hanse 40 to get ready for the Lake Ontario 300 and the Susan Hood Trophy Race this year. Last year's Lake Ontario 300 Scotch Bonnet line honour winner & Yachtsman's Cup winner Mike Brown also stopped by with his A3 and S2 to prepare for the season.

It was a great event, in conjunction with Lake Ontario Offshore Racing, which helped racers cross off another item on their to-do list for the season. Our Toronto team thanks racers for coming out!

Missed the event? Not to worry. Bring your sails in anytime and our service team can help get your sails measured & certified, both for PHRF and IRC ratings.

To learn more about LOOR's yacht racing/handicap requirements for racing, please see here for more detail.

Learn more about North Sails Certified Service and how it can help your sailing experience.

READ MORE

READ MORE

BESØG NORTH SAILS

BESØG NORTH SAILS

Forskellige bådtyper og forskellige interesser - North Sails dækker det hele

Har du lyst til og se et moderne sejlloft og de nyeste sejltyper og materialer?

Så inviter dig selv på en kop kaffe eller arranger, at din klub, klasse etc. kommer på besøg hos North Sails i Herlev.

”Vi får dagligt besøg af vores kunder og andre interesserede, som vil se vores topmoderne sejlloft. Ikke mindst er interessen for at se vores nye kompositsejl 3Di Nordac i polyester enorm.

Vi har 1000 kvadratmeter moderne faciliteter. Fx et sejlmagerbord på 400 kvadratmeter, hvor vi kan vise alle typer sejl og materialer,” fortæller loftmanager Jesper Feldt.

12-meter og Bavaria på besøg

Der har netop været besøg fra alle danske 12-meter både, og før det medlemmer af Dansk Bavaria Klub.

12-meter folkene oplevede en aften med fokus på den teknologiske udvikling hos North Sails med et oplæg fra designer Heine Sørensen.

Efterfølgende fortalte Mikkel Røssberg, der sejler professionelt på 18. år om kommunikation på båden under kapsejlads.

Det faldt i god jord hos de besøgende, der har et stort crew, hvor det kræver disciplin at få vigtig information tilbage til fx rorsmanden.

Designer Henrik Søderlund afsluttede med at fortæller om, hvordan man bedst tager foto og bruger anden teknologi til analysen af sejlegenskaberne, når båden og sejlene er i funktion.

Aftenen blev afsluttet på det store sejlmagerbord, hvor flere typer sejl kunne inspiceres.

Rullemaster og andre detaljer

På samme måde sluttede en aften for Dansk Bavaria Klub, der inden da have fået et oplæg omkring udviklingen af sejl og muligheder til netop deres typer af både. North Sails er eksperter i og lave sejl til rullemaster, som flere af Bavaria bådene er udstyret med.

”Vi har altid kaffe på kanden og er der særlige interesser, så giv os et kald i forvejen, så finder vi netop de sejl og materialetyper frem. Er I flere med samme interesser, så sammensætter vi gerne et program netop til jer,”, slutter Jesper Feldt.

North Sails kan træffes på 39 20 40 90 og besøges på adressen Lyskær 10 i Herlev

Der er altid flere North Sails-eksperter tilstede, som kan give råd og vejledning til de besøgende.

READ MORE

READ MORE

SERVICE TIP: DEALING WITH CORRODED ZIPPERS

SERVICE TIP: DEALING WITH CORRODED ZIPPERS

One of the more frequent service jobs we have here at North Sails revolves around sail bag zippers. They are easily over looked yet are a fundamental component of your sail.

To keep your zips functioning try these tips from our service manager Nick Beaudion:

Rinse the zipper cars with fresh water after use. This will greatly extended the life of your metal slider. Using the last bits of the crews water bottle at the end of the day is a simple solution.

Silicone spray your zipper cars. Any number of silicone sprays will accomplish the same goal of protecting the metal slider from salt water.

Keep your sails dry. After the fresh water rinse and silicone spray, storing your sails in a dry environment will greatly extend the life of the slide over longer periods of time.

If you do have a corroded zip there are a number of things you can do to rectify

Pour fresh, boiling water over the zip to help clear the sail buildup

Gently pull the zip apart and tap on the slider with a screwdriver. This will dislodge the sail buildup and help move the slider

If worse come to worse drop your sail bags off to your local North Sails service loft to have your old sliders replaced before your next big regatta

READ MORE

READ MORE

A NOD TO FEMALE SAILORS ON INTERNATIONAL WOMEN'S DAY

A NOD TO FEMALE SAILORS ON INTERNATIONAL WOMEN'S DAY

Celebrating 8 years in the sailing world through my lens

Sailing, as a kid, was something we did on weekends or at camp; never did it come into mind that it could be a career avenue. Growing up, I never would have thought I’d be working where I am today or in the industry I am. But now? I couldn’t imagine working anywhere else. The people you met, the stories you hear and the adventures you experience are some of the most unique that it will always keep you coming back for more. There’s never a dull day.

My start in the sailing industry began in high school when I took a summer job at a local chandlery with what I’d soon learn was minimal sailing knowledge. It was quite literally a whole new world I had just embarked on. Sure, I grew up sailing at camp and on the family boat here and there, but it was nothing compared to the world I was thrust into. Overwhelming to say the least but I was hooked. I returned for another summer the following year – and 6 more after that second one. Gradually learning more along the way while also getting out on the water more.

As time went on I noticed a great imbalance in the number of women in the industry though. There were a small handful of us who were familiar faces in the local sailing scene in Toronto, be it leisurely or professionally, creating a sense of community. The more involved I became the more I was introduced to this network of female sailors who welcomed you with opened arms, such as Kristina Gilbert. It’s been great to become a part of this community and help grow the sport.

After 10 years of volunteering on Race Committees and 4 years of participating with Club Level Racing, I can truly say that sailing is in my DNA. I have done everything from recording sail numbers to being RO on Race Committee; my passion though is mark setting. When it comes to racing, as with most, I started out as rail beef gradually transitioning into different positions throughout the boat. Currently, I am testing my skills as pit.

There is no better place to be than on the water and with the craziness of our daily lives, sailing is the one thing that makes my soul smile within two minutes of leaving the dock. At the end of the day it is exactly what the doctor ordered and spending time with people that have the same sort of passion for the sport is the cherry on top!

-Kristina Gilbert, Port Credit Yacht Club

I joined North Sails almost a year ago and have not looked back since. It has been a fantastic environment to learn and grow; one that encourages women to become more involved in the sport and overall community.

The past eight years as fantastic as they’ve been have not come without their own trials and tribulations. The sailing world is for the most part a male dominated industry with even greater inequality for women when it comes to the professional yachting industry. It’s a familiar scene walking the docks, crews upon crews getting ready to head out during weeknight racing or a weekend of racing. The ratio of men to women is probably 80 to 20. A ratio that needs to become more balanced.

We’ve seen teams like Team SCA from the 2014/2015 Volvo Ocean Race to Team Magenta 32 who competed in the World Match Racing Tour have helped change the stage for women in professionally yachting. Further changes such as the crew options for the 2017/2018 edition of the Volvo Ocean Race have also opened up new opportunities for female sailors to compete on a level playing field in professional yachting. While we have made great strides, there is still room for improvement. I have no fear that the tides are turning, and we will see the realm change for the better in the years coming.

Happy International Women’s Day to all!

Check out more leading ladies changing the tides in sailing.

READ MORE

READ MORE

GIORGIO TORTAROLO SCELTO COME SPECIALIST NORTH SAILS

SAIL AND VELERIES, GIORGIO TORTAROLO CHOSEN AS SPECIALIST NORTH SAILS

Carasco - A few weeks after the entry of Matteo Sangiorgi in the North Sails network, the Carasco sailmaker announces the entry of a new important reinforcement in the technical-commercial staff, that of Giorgio Tortarolo.

Winner of three world titles, two continental and five national, Tortarolo, already engaged on board the TP52 Orlanda and Anonymous, boasts affirmations in all the circuits connected to the Melges classes (20 and 32), including the newborn Melges 40 Grand Prix. In addition, the activity carried out in the maxi area is also of absolute level, thanks to its involvement in Stig's projects, protagonist on the international regatta fields with a Baltic 65 first and a Mini Maxi 72 then. Thanks to the highlights of a career dedicated to sailing and regattas, Giorgio Tortarolo obtained the titles of Azzurro d'Italia and was awarded the CONI of the Star for Sports Merit.

Backed by an experience of three hundred and sixty degrees deriving from having managed some of the shipyards, the last of which Savona ShipYard, Tortarolo, which in recent years has concentrated its competitive activity mainly on monotype, is ready to make available to North Sails and his clients as he matured in years of activity linked to sailing: "Being part of the North Sails network is undoubtedly a prestigious step in the career of every sailor. We are talking about a reference brand for each professional, one of the first to become familiar when deciding to devote himself to sailing and regattas. Over the years I have been able to appreciate the constant search for performance by North Sails: a goal pursued through major investments in research and development, that have equipped the technicians with the most modern and technologically advanced instruments and the boats of fast and reliable profiles. Moreover, looking beyond monotype, North Sails is a reference veil in the world of offshore and offshore regattas, areas that fascinate me because they leave great space for optimization and custom solutions ".

Available along the docks of the main Italian and international sailing events, Giorgio Tortarolo and his collaborators are available to customers at the North Service Point in the Marina di Varazze, where they offer services such as consultancy, sale and washing of sails and clothing supplies for crews.

Welcome to Tortarolo in the North Sails working group was the management of the Italian loft of Carasco: "Giorgio is one of the most active Italian sailors in the world of monotype: present at all the main events of the season, for years collaborating with the teams flagship and this makes it one of the most profound connoisseurs of the one design classes of reference. It is one of those elements able to make the difference, whose point of view helps to achieve the objectives to be achieved more effectively ".

READ MORE

READ MORE

NEWS – PARTENARIAT 2018 AVEC LE CHAMPIONNAT DU PETIT LAC

LE CHAMPIONNAT DU PETIT-LAC ET NORTH SAILS SUISSE SONT HEUREUX DE VOUS ANNONCER LA POURSUITE DE LEUR COLLABORATION POUR LA SAISON 2018.

L’équipe de North Sails sera présente sur la plupart des régates pour faire de jolis clichés afin de récompenser par des agrandissements photos les podiums de chaque classe en fin de saison lors de la soirée de gala qui se tiendra au Château de Bossey le 30 novembre.

L’action principale de cette collaboration sera de nouveau le coaching personnalisé, réalisé sur certaines épreuves du Championnat (hors Genève-Rolle-Genève, Bol d’Or et la Double). A noter qu’une fois un équipage tiré au sort, il ne pourra pas être sélectionné une deuxième fois (voir le règlement du tirage au sort dans le billet du CPL).

Dans une atmosphère conviviale et avec pour objectif de partager notre passion commune, ce coaching personnalisé comprendra les actions suivantes :

J-5 Lundi matin, tendance météo, check-list performance avec le skipper (carène, voiles à bord, électronique etc.), établissement de la liste d’équipage pour l’entraînement et la régate

J-4 Entrainement du mardi soir avec l’équipage complet (lieu à définir ensemble)

J-1 Briefing météo, réglage du gréement, lecture des instructions de course, derniers conseils pour la préparation du bateau

H-3 Météo finale, stratégie générale, check-list des priorités

H Suivi de la régate, photos et vidéos techniques, prise de notes ou navigation à bord

J+3 La semaine qui suit, débriefing avec l’ensemble de l’équipage autour d’un café à la voilerie (ou d’une bière J), avec analyse des photos/vidéos et établissement de la liste des points « à améliorer ».

Avec nous, les pros, c’est vous ! Nous partagerons nos trucs et astuces pour booster les performances de votre speedo, améliorer vos manœuvres en toute sécurité, affiner vos réglages et tactiques sur des bases simples mais efficaces.

Toute l’équipe North Sails Suisse, composée de Christine, Arnaud, Ben, Jonas, Julien, Michel, Nicolas, Patrick, Philippe, Pierre-Yves et Rata, est à votre service tout au long de l’année pour vous prodiguer de bons conseils en toute simplicité. Pour cela, un seul numéro, le 022 782 32 22 !

Nous tenons à remercier chaleureusement le Comité du Championnat du Petit-Lac pour le renouvellement de sa confiance et pour l’ensemble du travail accompli depuis plus de 40 ans.

Nous vous souhaitons à toutes et à tous une excellente saison et un super Championnat du Petit Lac 2018 !

Votre team North Sails Suisse

READ MORE

READ MORE

WHO WE ARE: HUGH BEATON

WHO WE ARE: HUGH BEATON

Get to know your local sales expert

What do you sail? How long have you been sailing?

I learned to sail in Barrie ON, working through Lasers, 470, International 14 and small keelboats.

What boats/classes do you sail?

Early in my career I was introduced to the International 8 Metre, which quickly became my class of choice working with over 40 boats from 12 countries. The boats are beautiful to sail, and highly technical making them an ideal platform for North Sails' range of design services and 3D manufacturing. I have attended 21 World Championships winning 9 titles along the way. It has been very rewarding to work with so many great sailors, and to develop products and tuning guides for the class.

Aside from the 8s, Hugh enjoys distance racing on the Great Lakes, and cruising with his family in the North Channel area of Lake Huron.

What got you into the marine industry?

I started in the marine industry by working at local sail loft during summers while attending the University in Toronto. During this time, I learned to design and build spinnakers - developing a passion for racing IOR boats throughout North America.

How long have you been working in the industry?

I joined North Sails in 1990 and was privileged to work with some great people in the Toronto office: Hans Fogh, Steve Calder, Bruno Dubois, Larry MacDonald to name a few.

READ MORE

READ MORE

WHO WE ARE: LOUISA SONOSKY

WHO WE ARE: LOUISA SONOSKY

Get to know your local sales expert

What do you sail? How long have you been sailing?

I’ve been sailing since I was a kid in middle school flipping between dinghies and keelboats. I grew up sailing Hobie’s and Laser’s at camp while my father had a Beneteau 36.7.

What boats/classes do you sail?

The last classes I sailed were J/24s and Beneteau 36.7s.

What got you into the marine industry? What’s your favorite aspect of working in the industry?

I started in the marine industry through a Summer job at a local chandlery, Fogh Marine, and ended up working there for 7 years; learning just about everything I could about sailboats. I definitely was not the most knowledgeable when I started as I had taken a bit of a hiatus from sailing during my teenage years, but over the years I learned a ton thanks to colleagues and customers. My favorite aspect of working in this industry is getting to spend time on the water and photographing regattas.

What is your earliest sailing memory?

My earliest sailing memory is sailing at camp. It was a sunny – but chilly – day and they took us out in a small Hobie Bravo.

How long have you been working in the industry? What keeps you coming back for more?

I have been working in the marine industry for 8 years now – time flies. For me, what keeps me coming back is the people you meet and the stories they have! Everyone has a story and it’s great getting to know the different paths everyone took to get into sailing.

If you could have any boat in the world, what would it be? And why?

I’ve always wanted a J Boat; either a J105 or J97E. Photographing J Boats has always been one types of boats to photograph – the crisp lines can’t be beat.

READ MORE

READ MORE

OUR TYPICAL MORNING REGIMENT, ONE FLAKE AT A TIME

OUR TYPICAL MORNING REGIMENT, ONE FLAKE AT A TIME

A birdseye view of a typical morning with our service team at the North Sails Toronto loft

Kidd and Joel hard at work on varies sails in for our 10 Point Inspection. They provide a glimpse into a typical morning at the loft, demonstrating a sails journey from start to finish when in for service. While Summer is the height of our teams’ busy season, they are equally full during the offseason getting everything ready for another season on the water. Sail washing is our most popular offseason service type.

https://youtu.be/dCObHN7ODo4

READ MORE

READ MORE

THE IMPORTANCE OF SAIL SELECTION

THE IMPORTANCE OF SAIL SELECTION

Shane Hughes tells us about the A-Zero and the longevity of North sails onboard Melges 32 ‘Red’ at the Regata Chiloe Santander in Chile

This January, North Sails Shane Hughes left the cold Irish weather and the Northern hemisphere behind and headed south to Chile to compete in the bi-annual Regata Chiloe, one of Chile’s biggest and most prestigious regattas based around the beautiful southern island of Chiloe and the protected waters between it and the Chilean mainland. Shane had been invited by Pablo Anfruns and Rudolf Mijac to race with their team on the Melges 32 Red. For those who have not experienced it, Melges 32 racing is fantastic fun. The boat is very powered up and can easily sail in as little as 4 knots of wind but really comes into her own in 15 knots plus downwind! Having had a break away from sailing the 32 for a few years, it reminded me what a truly special boat it is. With only one other Melges 32 based in Chile right now (the newly acquired ‘Pepe Pato’ owned by Jose Tirado and Patricio Lopez) both boats were entered into the IRC division, not historically the Melges 32’s strong point with its big sail area and light displacement. So expectations were set firmly in pessimistic mode. However, Shane underestimated how the format of the regatta along with the traditional winds for this event (light!) would play into the Melges’ strengths rather than its weaknesses. Thankfully Pablo, the helmsman, and co-owner had not overlooked these factors and this had formed his reasoning for purchasing the Melges 32. The regatta format is a mix of coastal races, with some inshore windward-leeward races. While the 32 would struggle a little on some of the inshore races, the longer coastal races actually suited the boat, especially with downwind or light upwind legs.

©Regatachiloe.cl

One area of concern in the lead up to the regatta was the absence of a Code Sail on the Melges 32. The boat had been almost exclusively raced in One Design configuration, with no need for any code sails, but this regatta format demanded a sail that would work on the reaching and super light wind legs. With the help of Dave Lenz in the North Sails UK design office, we set about designing an A-Zero for the race. With such a long bowsprit the Melges 32 does not offer the option to set a true Code Zero sail, as you can not generate the cable/luff tension required to furl the sail properly thus the choice of an A-Zero which is hoisted, deployed and retrieved the same as any other spinnaker onboard. This in itself presents a challenge because if you build the sail from too stiff a material (laminate or 3Di) the sail will be very difficult to hoist and recover through the fore-hatch but use a softer nylon material and the sail will not have the stability to retain its flying shape, especially as an IRC zero which requires a big mid girth (>75% of foot length) . The compromise we struck was with Contender’s MaxiKote 200P. A great choice that produced a really stable sail shape that was easy for the crew to handle and work with. We also added North’s Velcro stop tabs which allowed us to roll the head and tack sections to make strong wind hoists easier and safer. The sail performed superbly and despite us using it infrequently (as is often the case with code sails!) it ended up winning us a coastal race where we were trailing our opposition Melges 32 for 70% of the race up until we hit a parking lot under a headland. They hoisted their biggest A2 Asymmetric and we hoisted our A Zero. From 100 meters behind, we sailed straight by them and even caught up to the other boats in our size range! We hit the new breeze first and won the race by some distance! The lesson learned, bigger is not always better especially in very light conditions. Shane stated:

"We used a full North Sails inventory, which bar the new A Zero, was from 2011 when the boat competed in its last World Championships in Palma. The Main and J1/Light jib were 3DL, while the J2 and J3 were 3Di Endurance. The A-2 asymmetric we used was a little newer, both made of AirX nylon. It really was a testament to the durability of both 3DL but especially 3Di that the sails had retained their flying shapes incredibly well. Granted they had not been used extensively in the interim but as you will see in the below pics, you would not guess they were 7-year-old sails."

The 3DL sails were just beginning to show the first signs of de-lam in high-density fiber areas and while this did not affect the performance of the sail at all, it does highlight what a huge advantage 3Di has over all of the ‘string’ sails from this perspective. The 3Di sails still looked brand new! No ill effects of being sat in the bag for that extended period. Unfortunately, the predominantly light winds meant they mostly remained in their bags, but the J1 held up superbly and ended up being the workhorse headsail for the team. At the end of a thoroughly enjoyable weeks racing, both Melges 32’s ended up at the top of the leaderboard with our team taking the win. This surpassed expectations on all fronts for the owners, especially in their first year in the boat. This promotes the future growth of the Melges 32 in Chile. There was quite a lot of interest in the boat, especially regarding its performance against other boats of similar size in the coastal races. Find out what we can do to improve your sail inventory or get in touch with one of our experts here!

©Benjasans.com

©Regatachiloe.cl

READ MORE

READ MORE

RORC CARIBBEAN 600: BAM SAILS TO WIN HER CLASS

RORC CARIBBEAN 600: BAM SAILS TO WIN HER CLASS

BAM wins her class in RORC Caribbean 600 crediting North Sails speed and reliability

Conor Fogerty, skippering the smallest boat in the fleet, his Jeanneau SunFast 3600 BAM, won his class in the RORC Carribean 600. The race was very windy with Conor and his team emerging victorious after five days of wet and wild racing. Conor has been working on his sail inventory with Maurice ("Prof") O'Connell from North Sails Ireland since the first launch of "BAM" in 2015, notching up an OSTAR win and a previous class win in the C600 in 2016. He took delivery of a new 3Di offshore main just prior to the C600 this year.

Speaking after the race Conor was fulsome in his praise of North Sails ;

"The new main is perfect, it was great to be able to totally rely on our sails, whilst boats around us dropped off due to sail failure. "BAM" returned to Antigua with a full intact wardrobe, and a class win which were are delighted with!"

Congratulations also to the HYC team on Pata Negra who finished 2nd in their class. Great racing for Irish offshore teams!

© RORC Racing / Tim Wright

© RORC Racing / Tim Wright

© RORC Racing / Tim Wright

© RORC Racing / Tim Wright

READ MORE

READ MORE

GREAT LAKES. GREAT RACES.

GREAT LAKES. GREAT RACES.

Our Top 5 To Tackle

A perfect combination of pristine waters, spectacular scenery and ever changing weather conditions makes the Great Lakes an exciting place for sailors of all levels. Distance racing in this unique environment can teach even the oldest dog new tricks. From helming, sail trim, navigation and night sailing, the entire crew can take part and experience the thrill of offshore racing. Our team have picked their favorite races across the Great Lakes to take on this year, have you signed up to any yet?

“The Bayview Mac is more than a race, it's a life experience. From week long activities leading up to the start, to the awards party on the island, there is fun for everyone! This race draws more attention to the sport we love, and in my 30+ years of taking part in this race, I have been able to share experiences with so many other racers. Once you have sailed it with someone, you have developed a lifelong bond.”

- Karl Kuspa, North Sails Expert, Detroit.

Register now to start planning your season of sailing and talk to your local team about how North Sails 3Di is the #1 choice for offshore distance racing.

Lake Erie Interclub Cruise

Lake Ontario 300

Bell's Beer Bayview Mackinac Race

CYC Race To Mackinac

Lake Superior International Offshore Series

READ MORE

READ MORE

GREAT LAKES. GREAT RACES.

GREAT LAKES. GREAT RACES.

Our Top 5 To Tackle

A perfect combination of pristine waters, spectacular scenery and ever changing weather conditions makes the Great Lakes an exciting place for sailors of all levels. Distance racing in this unique environment can teach even the oldest dog new tricks. From helming, sail trim, navigation and night sailing, the entire crew can take part and experience the thrill of offshore racing. Our team have picked their favorite races across the Great Lakes to take on this year, have you signed up to any yet?

“The Lake Ontario 300 has become one of the most significant races on Lake Ontario, entering its 29th edition in 2018. Having done this race many times, including the first one in 1990, I have learned something new each time. One of the most important takeaways from races like this is the value of seamanship and thoroughly enjoying your time on the water.”

- Hugh Beaton, North Sails Expert, Toronto.

Register now to start planning your season of sailing and talk to your local team about how North Sails 3Di is the #1 choice for offshore distance racing.

Lake Erie Interclub Cruise

Lake Ontario 300

Bell's Beer Bayview Mackinac Race

CYC Race To Mackinac

Lake Superior International Offshore Series

READ MORE

READ MORE

SPEAKERS NIGHT WITH LAKE ONTARIO OFFSHORE RACING

SPEAKERS NIGHT WITH LAKE ONTARIO OFFSHORE RACING

An evening of seafaring stories & laughs

Racers gathered this past Wednesday at Port Credit Yacht Club to share their tales from the race course. Countless stories were told from years past with many racers highlighting favourite seconds from the Lake Ontario 300 and the Susan Hood Trophy Race.

Local North Sails expert, Hugh Beaton, was on hand to partake in the evening with North Sails Toronto providing several swag prizes.

READ MORE

READ MORE

GREAT LAKES. GREAT RACES.

GREAT LAKES. GREAT RACES.

Our Top 5 To Tackle

A perfect combination of pristine waters, spectacular scenery and ever changing weather conditions makes the Great Lakes an exciting place for sailors of all levels. Distance racing in this unique environment can teach even the oldest dog new tricks. From helming, sail trim, navigation and night sailing, the entire crew can take part and experience the thrill of offshore racing. Our team have picked their favorite races across the Great Lakes to take on this year, have you signed up to any yet?

“CYC's Race to Mackinac remains the single most important focus for many Lake Michigan Sailors. Not only does the race end in a truly beautiful and fun spot, but it offers uniquely different and challenging conditions along the way - from excruciatingly slow drifting to exhilarating summer thunder storms, to upwind bashing.”

- Perry Lewis, North Sails Expert, Chicago.

Register now to start planning your season of sailing and talk to your local team about how North Sails 3Di is the #1 choice for offshore distance racing.

Lake Erie Interclub Cruise

Lake Ontario 300

Bell's Beer Bayview Mackinac Race

CYC Race To Mackinac

Lake Superior International Offshore Series

READ MORE

READ MORE

NORTH U TRIM SEMINARS COMING TO THE MIDWEST

CALLING ALL SAILORS IN THE MIDWEST

North U Trim Seminars Are Coming To A City Near You!

The North U Racing Trim Seminar is offered as a one-day course focusing on boat speed and sail trim, and it's coming to your city! Two locations, back to back, Chicago and Milwaukee. Get the most out of your sailing experience and up your game on the race course!

WHERE?

CHICAGO-MARCH 3RD

DePaul University

Lincoln Park Campus

2320 N. Kenmore Ave.

Chicago, IL 60614

(near Fullerton & Halsted)

Seminar Location: Schmitt Academic Center

Room: SAC-161

MILWAUKEE- MARCH 4TH

Hosted by the University of Wisconsin-Milwaukee Sailing Team!

University of Wisconsin-Milwaukee

3210 N. Maryland Avenue

Milwaukee, WI 53211

Seminar Location: Lubar School of Business

Room: TBA

Can’t make a seminar in your location? Try our Trim Webinar, available on-demand anytime.

“You’ve got to be fast to win!”

North Sails President Ken Read – AC TV commentary

Turning sailors into racers and racers into winners. Sign up HERE!

READ MORE

READ MORE

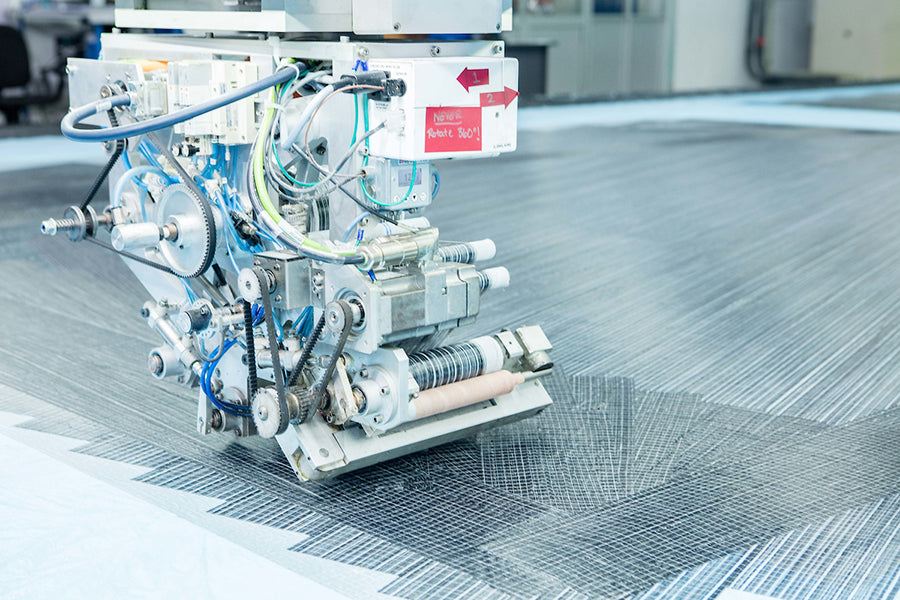

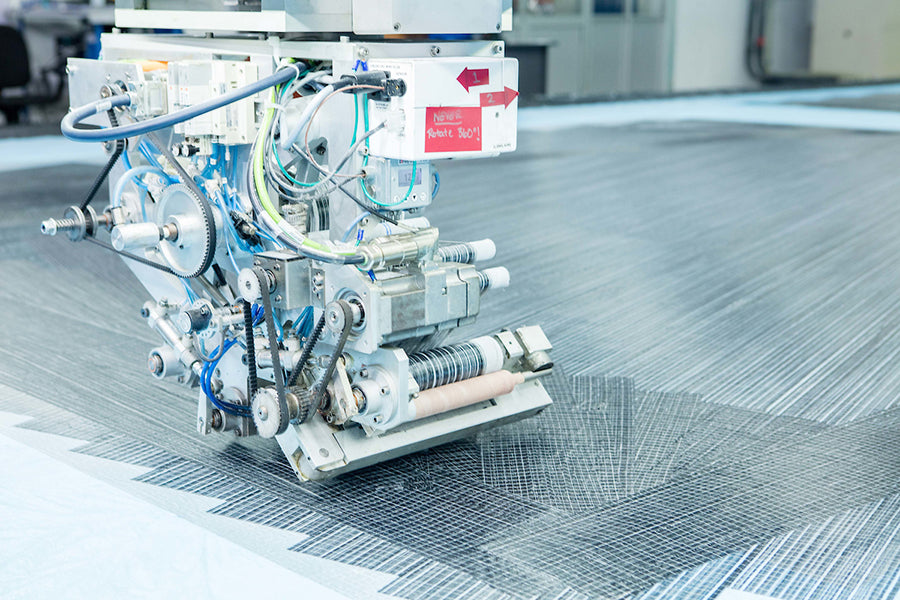

NORTH SAILS COMPLETA SU EVOLUCIÓN HACIA LA TECNOLOGÍA 3Di

NORTH SAILS COMPLETA SU EVOLUCIÓN HACIA LA TECNOLOGÍA 3Di

El comienzo de 2018 marca un hito en la historia de North Sails. La velería líder mundial completa un ciclo de diez años de transformación desde su tecnología de 3DL, velas laminadas en 3D, a estructuras de composite moldeadas 3Di. Las plantas de la firma en Minden (Estados Unidos) y Sri Lanka ya sólo fabrican 3Di, la vela de mayor éxito de la historia.

North Sails lideró la tendencia de construcción laminada de mylar e hilo con sus revolucionarias velas 3DL, que dominaron la velería de altas prestaciones desde principios de 1990 hasta la America’s Cup de 2007. Con la aparición del 3Di, la compañía fue abandonando la producción de velas laminadas a favor de estructuras 3D de composite con filamento esparcido y preimpregnadas. Las velas 3Di proporcionan propiedades de conservación de la forma y de durabilidad muy superiores a cualquier otra vela de construcción laminada. El moldeado en tres dimensiones a escala real es la piedra angular de la tecnología North Sails.

Desde que el sindicato suizo Alinghi sorprendió a la comunidad de la vela probando estructuras 3Di en preparación para la defensa de la 32 America’s Cup en Valencia, el concepto 3Di no ha dejado de evolucionar y expandirse a lo largo y ancho del extenso catálogo North Sails, y hoy está disponible para todo tipo de embarcaciones, de grand prix a monotipos, de superyates a cruceros. La introducción el pasado año de las 3Di NORDAC para crucero y 3Di RAW 760S para regata supuso la aplicación del 3Di a barcos de menor eslora y su consiguiente popularización.

En respuesta a una demanda en constante crecimiento, North Sails ha ido adaptando sus instalaciones de producción en Minden (especializada en velas grand prix y de superyates) y Sri Lanka (barcos hasta 50 pies de eslora) a medida que la tecnología evolucionaba de velas de paneles y 3DL a 3Di. La última línea de producción de 3DL se cerró definitivamente en septiembre de 2017, y hoy las dos factorías fabrican exclusivamente 3Di. North Sails cuenta con líneas de preimpregnado idénticas en ambas plantas trabajando 14 turnos por semana, con siete líneas ATL (Automated Tape Laying o sistema de colocación automático de cintas) en Minden y otras cinco en Sri Lanka funcionando 24 horas al día y siete días por semana. Las líneas de preimpregnado y ATL alimentan ocho grúas y diez moldes a escala real ajustables de 3D.

Dan Neri, director general de North Sails, explica la evolución de la estrategia de producción de la firma: “La expansión de la factoría de Sri Lanka responde al éxito de la nueva 3Di RAW 760S para barcos de competición de menor tamaño y de la 3Di NORDAC para cruceros de pequeña eslora. Las velas 3Di siguen respondiendo a las necesidades de navegantes de todas las clases, desde Skiffs de 18 pies en Australia hasta la flota Ultime de 100 pies en Francia. Nuestra tecnología está detrás de un número sin precedentes de victorias en regata y de récords mundiales, además de infinidad de historias de cruceristas gracias a la consolidación de la 3Di NORDAC entre la comunidad de crucero”.

La planta 3D Minden es el centro de referencia para investigación de materiales, ingeniería y fabricación de productos tridimensionales, exclusivos de North Sails. Por su parte, Sri Lanka Manufacturing cuenta con instalaciones de última generación que ocupan a cerca de 1.200 personas distribuidas en ocho edificios. Ambos centros de producción envían las velas 3Di a todo el mundo.

La gama North Sails 3Di incluye las líneas 3Di RAW, 3Di ENDURANCE, 3Di NORDAC y 3Di Downwind.

Para más información sobre las velas North Sails 3Di, visita www.northsails.com o contacta con nosotros en info@es.northsails.com

READ MORE

READ MORE

WELCOME TO THE MIDWEST

WELCOME TO THE MIDWEST

Our Midwest Team Welcomes A New Expert

We are pleased & excited to welcome Allan Terhune back to North Sails and introduce him to our Midwestern sailors!

Many of you know that we have had a consistent veteran staff for quite a long time now – Perry Lewis has been a mainstay here nearly 40 years, Tom Pease (North Sails in Milwaukee) has been with the company for just as long, Luke Logan has been Service Manager approaching 20 years, and Deanna Trejo has been managing our office for nearly 5 years. So it is high time to welcome a new face!

Allan brings a fresh enthusiasm along with a wealth of experience & knowledge. His extensive sailing resume, both racing & coaching expertise speaks for itself. Allan has built a foundation in competitive One-Design classes, while maintaining his most important interest in helping sailors at all levels achieve maximum performance. We know that he will be a valuable asset to our team in providing superior service, both to our existing client base as well as to newcomers.

Welcome Allan- We are proud to have you on our team!

READ MORE

READ MORE

TIPS FOR TAKING PROPER SAIL SCAN PHOTOS

TIPS FOR TAKING PROPER SAIL SCAN PHOTOS

Investigating your sail twist profile with onboard imagery

First, position your camera(phone) at the mid‐foot area of your sail. Angle your camera to catch all three draft stripes from luff to leech. Usually the bottom stripe will have one end in a corner and the other end in the opposite, higher or lower corner of the frame.

To get a good angle of your headsail, you'll need to get down to deck level, so lay on your back and shoot up from the middle of the foot. (Hopefully a friend is driving, especially if it’s choppy!)

To get a good image of your mainsail, you'll need to position your camera so the angles are similar, and at the same time try to include the center of the boom in the bottom of the photo to assure you are in the right place. This will help us calculate the twist profile when the photo is measured by your sail expert.

READ MORE

READ MORE

CRECE LA FAMILIA NORTH SAILS PALMA

CRECE LA FAMILIA NORTH SAILS PALMA

North Sails anunció el pasado mes de enero la incorporación de Doyle Palma al equipo de superyates de North Sails Palma.

Quinten “Quinny” Houry, Fiona Bruce y Russell Thom, respetados especialistas en fabricación de velas de superyates, refuerzan el potente equipo de la velería de Palma, una de las 16 específicas para superyates que North Sails posee en todo el mundo.

READ MORE

READ MORE

NORTH SAILS COMPLETA SU EVOLUCIÓN HACIA LA TECNOLOGÍA 3Di

NORTH SAILS COMPLETA SU EVOLUCIÓN HACIA LA TECNOLOGÍA 3Di

El comienzo de 2018 marca un hito en la historia de North Sails. La velería líder mundial completa un ciclo de diez años de transformación desde su tecnología de 3DL, velas laminadas en 3D, a estructuras de composite moldeadas 3Di. Las plantas de la firma en Minden (Estados Unidos) y Sri Lanka ya sólo fabrican 3Di, la vela de mayor éxito de la historia.

North Sails lideró la tendencia de construcción laminada de mylar e hilo con sus revolucionarias velas 3DL, que dominaron la velería de altas prestaciones desde principios de 1990 hasta la America’s Cup de 2007. Con la aparición del 3Di, la compañía fue abandonando la producción de velas laminadas a favor de estructuras 3D de composite con filamento esparcido y preimpregnadas. Las velas 3Di proporcionan propiedades de conservación de la forma y de durabilidad muy superiores a cualquier otra vela de construcción laminada. El moldeado en tres dimensiones a escala real es la piedra angular de la tecnología North Sails.

Desde que el sindicato suizo Alinghi sorprendió a la comunidad de la vela probando estructuras 3Di en preparación para la defensa de la 32 America’s Cup en Valencia, el concepto 3Di no ha dejado de evolucionar y expandirse a lo largo y ancho del extenso catálogo North Sails, y hoy está disponible para todo tipo de embarcaciones, de grand prix a monotipos, de superyates a cruceros. La introducción el pasado año de las 3Di NORDAC para crucero y 3Di RAW 760S para regata supuso la aplicación del 3Di a barcos de menor eslora y su consiguiente popularización.

En respuesta a una demanda en constante crecimiento, North Sails ha ido adaptando sus instalaciones de producción en Minden (especializada en velas grand prix y de superyates) y Sri Lanka (barcos hasta 50 pies de eslora) a medida que la tecnología evolucionaba de velas de paneles y 3DL a 3Di. La última línea de producción de 3DL se cerró definitivamente en septiembre de 2017, y hoy las dos factorías fabrican exclusivamente 3Di. North Sails cuenta con líneas de preimpregnado idénticas en ambas plantas trabajando 14 turnos por semana, con siete líneas ATL (Automated Tape Laying o sistema de colocación automático de cintas) en Minden y otras cinco en Sri Lanka funcionando 24 horas al día y siete días por semana. Las líneas de preimpregnado y ATL alimentan ocho grúas y diez moldes a escala real ajustables de 3D.

Dan Neri, director general de North Sails, explica la evolución de la estrategia de producción de la firma: “La expansión de la factoría de Sri Lanka responde al éxito de la nueva 3Di RAW 760S para barcos de competición de menor tamaño y de la 3Di NORDAC para cruceros de pequeña eslora. Las velas 3Di siguen respondiendo a las necesidades de navegantes de todas las clases, desde Skiffs de 18 pies en Australia hasta la flota Ultime de 100 pies en Francia. Nuestra tecnología está detrás de un número sin precedentes de victorias en regata y de récords mundiales, además de infinidad de historias de cruceristas gracias a la consolidación de la 3Di NORDAC entre la comunidad de crucero”.

La planta 3D Minden es el centro de referencia para investigación de materiales, ingeniería y fabricación de productos tridimensionales, exclusivos de North Sails. Por su parte, Sri Lanka Manufacturing cuenta con instalaciones de última generación que ocupan a cerca de 1.200 personas distribuidas en ocho edificios. Ambos centros de producción envían las velas 3Di a todo el mundo.

La gama North Sails 3Di incluye las líneas 3Di RAW, 3Di ENDURANCE, 3Di NORDAC y 3Di Downwind.

Para más información sobre las velas North Sails 3Di, visita www.northsails.com o contacta con nosotros en info@es.northsails.com

READ MORE

READ MORE

WHO WE ARE: JOEL CARO

WHO WE ARE : JOEL CARO

Get to know your local sales expert

Joel Caro is from Toronto, Ontario and started Sail-making/Sailing in Santiago, Chile in the early 90's at "Mississauga Sails", his family Sail Loft. He attended INACAP Institute for Engineering in International Business.

What do you Sail? How long have you been sailing?

I mostly sail One Design Classes from Wayfarers, Snipe, SR-21 to Etchells, Soling, C&C, J/24, J/105 and J/122. I have been sailing since 1993, so around 25 years now.

What Boats/Classes do you sail in?

I currently sail in the local J/105 Fleet 4 One Design Class here in Toronto.

What got you into the marine industry? Favorite aspect of working in the industry?

My family comes from a Sail-making background, both my parents started sail-making with Hans Fogh at Fogh Sails and then later North Sails Fogh Toronto back in the late 70's. I basically grew up in that Sail loft in Toronto, so I started learning the trade at a young age.

My favorite aspect of working in the industry is being able to work in something that I love to do and to give our customers the best sails in the world while also delivering exceptional customer service. Another favorite aspect is being able to sail on different sailboats with customers with our sails.

How long have you been working at/with North Sails?

I have been working at North Sails since 2013.

What is your earliest/favorite sailing memory?

My earliest/favorite sailing memory would have to be when I was living with my family in Santiago, Chile, we had our own sail loft which we named " Mississauga Sails " (Mississauga is the city we used to live in). One of our customers called to ask if I wanted to go sailing on his J/24 at a regatta on Lake Rapel. I was 15 or 16 at the time and I said sure, let's go (it would be my very first regatta and I had no idea how to sail).

My skipper picked me up and he said the rest of the crew would meet us there, and so the drive from Santiago to Lake Rapel is around 2 hours, so as we are driving about 10 minutes in, I ask why are we heading to the airport and he replied, "we are going in my plane".

Long story short, I had no idea my skipper had a plane and that we were going to fly to this weekend regatta, so you can imagine the excitement, the flight was awesome and only took 20 minutes, we won the weekend regatta and we flew back to Santiago with the crew. The whole experience was amazing.

How long have you been working in the industry? What keeps you coming back for more?

I have been a sailmaker for 25 years, and I enjoy the competition and sailing with our customers with our sails.

If you could have any boat in the world, what would it be? And why?

It would have to be the DNA F4, which is an exciting Carbon 46 foot Foiling One Design Catamaran; designed and built to push the boundaries of long distance sailing (and because I like to sail fast).

What's your best advice for sailors when it comes to sail care?

My best advice for sailors when it comes to sail care (this goes for both cruising and racing) is to take care of your sails (they are not cheap!). They are the engines for your sailboat, just like a vehicle, your engine needs maintenance and repairs, so bring in your sails at the end of the season for a Full 10-Point Inspection. This ensures your sails are in top condition for the following season. Lastly, make sure to store your sails properly, in a dry area and in a pest free environment.

READ MORE

READ MORE

O'LEARY BROTHERS WIN STAR MID-WINTERS

O’LEARY BROTHERS WIN STAR MID-WINTERS

Congratulations to Peter and Robert O'Leary for winning the Star Mid-Winters and the Walker Cup last weekend. Peter has returned to the Star class to race with his younger brother Robert as his crew. The full family compliment was on hand for the first regatta with father Anthony in the coach boat.

Peter and Robert launched a brand new Star for the regatta and she was fully equipped with sails from North. Nigel Young from North Sails Ireland has been working with Peter in the Star class since 2010 and is delighted to play a small part in this campaign.

We can expect to see more great results from this Team as the season unfolds, good luck from us all here at North Sails Ireland.

Full results

READ MORE

READ MORE

WHO WE ARE: GEOFF MOORE

WHO WE ARE: GEOFF MOORE

Get to know your local sales expert

Geoff Moore with Zingara boat owner Richard Reid at the 2017 Beneteau 36.7 World Cup in Helsinki, Finland.

Geoff Moore is a Rhode Island native who grew up sailing in New England. He attended the University of Rhode Island for Political Science. Since 2002, he has been with North Sails Toronto.

What do you sail? How long have you been sailing?

I have been competitively racing sailboats since 1974.

What boats/classes do you sail?

All types of dinghies, Lasers, Sunfish, Lightnings, Snipes, Albacore, Interclub dinghies, I14s, all manner of US collegiate dinghies.

Small keelboats, J/24, J/22, Etchells, Shields, Sonars, Ideal 18's, IOD's, Stars, J/80's, J/70's, Melges 20's, 24's, and 32's, Farr 30s , and C&C’s every size.

Larger One Design Keel boats, Farr 40, J/105s, J/30s, J/35s, J/111, Beneteau 36.7, Beneteau 40.7, Swan 42. 6 Meters, 8 Meters, 12 Meters.au 40.7, and the Swan 42.

And, of course too, many handicappers, and cruising boats to list here.

What got you into the marine industry? What’s your favorite aspect of working in the industry?

I have always been passionate about sailboats, and specifically about how sail shape affects their performance. The technology has always fascinated me. Whether it be woven textile science, or spread filament, molded, composite, membranes, the goal is always the same, to construct sails light in weight, exquisitely shaped, with the least possible distortion under load. Achieving one or two of those objectives is rather easy these days. North Sails is a company full of highly motivated people who are committed to the challenge of achieving all three objectives. That makes it an exciting and challenging place to be. Delivering beautiful sails, and witnessing first hand, how they enhance our client’s enjoyment of their boats is by far the best part of this job.

What is your earliest sailing memory?

My earliest sailing memories were as a very young child, with my younger brothers, and parents, sailing aboard our Alberg 23 “Winsome” upon the waters of Narragansett Bay and Rhode Island Sound. On weekends we would visit various harbors and anchorages, taking time to swim, dig for clams, fish, and learn about the ocean and sailboats. In those days there were always 12 Meters about training for the America’s Cup. It seemed to me that they had always been there, and they would never leave. The America’s Cup is now gone, but the 12 Meters, and their legacies, are still there.

How long have you been working in the industry? What keeps you coming back for more?

I get a kick out of learning and sharing little tricks about how to make sails perform better. It still excites me to help install beautiful new sails. I don’t think I will ever lose interest in that.

If you could have any boat in the world, what would it be? And why?

What kind of question is that! It is like asking someone to pick a favorite child. And, how could I possibly pick just one. I believe all sailboats have some merit, if not in their performance, then certainly in their history. Someone had to conceive and then construct every sailboat. To build a boat is not a trivial endeavor. If pressed I think I would not be alone in choosing a boat that was the most popular One Design fleet in the area where I lived. Beyond that it is fun to race fast boats on big open water, and slow boats in confined harbors. It is nice to do a little of both.

READ MORE

READ MORE

BAM GEARS UP FOR CARIBBEAN 600

BAM GEARS UP FOR CARIBBEAN 600

North Sails Ireland are delighted to play a part in the success of BAM with Conor Fogerty

Conor had the following to say to us at the Volvo Sailing awards night:

"North Sails have been a key part of the BAM story since her first launch in 2015. The new J2 and J5 played a key part in the OSTAR 2017 and I am looking forward to racing with the new 3Di mainsail for the RORC Caribbean 600 race in 2018"

North Sails Ireland supplied the first inventory for Conor back in 2015 with which he won his class in the 2016 RORC Caribbean 600 race. These sails were a mix of 3DL and 3Di plus the Nylon downwind sails.

In early 2017, for his epic OSTAR-winning attempt, NS Ireland supplied a new 3Di Code 2/3 reefing jib and a No. 5 "Radian" jib for exceptionally heavy upwind work. These sails did the business for Conor and BAM as she took first place in the Gypsy Moth Class in the OSTAR.

We have also just supplied a new 3Di offshore main for his 2018 RORC Caribbean 600 Race which starts very soon!

Good Luck with that one Conor, we will all be watching with interest.

Click here to follow the Caribbean 600

READ MORE

READ MORE

NORTH U TERMINE 2018

NORTH U TERMINE 2018

Bevorstehende Termine

TERMINE

13.-15. April 2018

North U 2018 / 1 - Neusiedlersee - auf Lago 26

Freitag, 13. April um 18:00

Begrüßung und Überblick zur North Sails University mit Einführungsvortrag über Segeltrimm vom Trainerteam

Aufnahme individueller Schwerpunkte der einzelnen Teilnehmer

Samstag, 14. April 2018 und Sonntag, 15. April 2018

Theorie Einheit(en) und Beobachtung am Wasser mit direktem Feedback (Einsatz von Funkhelmen)

Debrief mit Foto- und Videoanalyse im Anschluss an die Wasserarbeit

Teilnahmebeitrag

€ 595,00 (Trimmvortrag, Bootsmiete, Training) pro Teilnehmer

Bei weniger als 10 angemeldeten Personen können wir die Veranstaltung leider nicht durchführen – wir bitten um Verständnis.

25.-27. Mai 2018

North U 2018 / 2 - Attersee – YST LM OÖ – auf eigenen Booten

Freitag, 25. Mai um 18:00

Begrüßung und Überblick zur North Sails University mit Einführungsvortrag über Segeltrimm vom Trainerteam

Aufnahme individueller Schwerpunkte der einzelnen Teilnehmer

Samstag, 26. Mai 2018 und Sonntag, 27. mail 2018

Beobachtung am Wasser bei den Wettfahrten mit der Möglichkeit des direktem Feedback nach dem Zieldurchgang

Debrief mit Foto- und Videoanalyse im Anschluss an die Wettfahrten

Teilnahmebeitrag

€ 195,00 Skipper und Boot

€ 50,00 für jedes weitere Crewmitglied – maximal € 150,00

(inklusive Trimmvortrag, Analyse der Wettfahrten, individuelle Betreuung und Dokumentation)

Bei weniger als 10 angemeldeten Personen können wir die Veranstaltung leider nicht durchführen – wir bitten um Verständnis.

Inhalte

Jeder Regattasegler möchte gerne das Potential von Schiff und seiner Mannschaft ausschöpfen und erfolgreich segeln, sich weiterentwickeln und im besten Fall gewinnen. Regattasegeln ist ein komplexes Unterfangen: Trimm, Taktik, Boat Speed, Steuern, Regeln, Bootshandling, Crewarbeit... aber bekanntlich ist eine gute Bootsgeschwindigkeit ein wesentlicher Schlüssel zum Erfolg.

Nicht immer sind dafür neue Segel notwendig, meistens gehören sie nur richtig eingestellt!

Daher bieten wir ihnen die Möglichkeit mit Wissen und Praxis ihr Schiff und ihre Segel optimal einzustellen und das Erlernte sofort umzusetzen. Der Schwerpunkt der North Sails University liegt auf dem Segeltrimm. Fragen, Wünsche und „Problemzonen“ jedes einzelnen Teilnehmers werden vorab besprochen und der Fokus bei den Segelaufnahmen danach ausgerichtet. Das neue und aufgefrischte Wissen über seine eigenen Segel und den eigenen Trimm ist sicher für die gesamte Segelsaison äußerst nützlich!

Ablauf

Ein strukturiertes, auf die individuellen Bedürfnisse und Wünsche der Teilnehmer abgestimmtes Programm – wobei wir Sie eine Runde um den Regattakurs begleiten - hält die Balance zwischen theoretischem Input, eigener Umsetzung und direktem Feedback am Wasser. Das am Freitag im Vortrag erlernte Trimmwissen wird bei den Wassereinheiten Samstag und Sonntag in der Praxis angewandt. Die professionelle Dokumentation der schnellen Boote mit Hilfe von Fotos und Videos - sowie die Herausarbeitung der Unterschiede zu den weniger schnellen - erfolgt an beiden Tagen nach der Wasserarbeit im Rahmen eines Debriefing.

Bei weniger als 10 angemeldeten Personen können wir die Veranstaltung leider nicht durchführen – wir bitten um Verständnis.

North U

Die North Sails U. wurde 1980 in den USA gegründet mit den klaren Zielen:

Segler zu Regattaseglern und Regattasegler zu Siegern zu entwickeln. Sind sie in Österreich mit dem gleichen Zielen dabei und kontaktieren sie unser Trainerteam.

Ihr Trainerteam

Für Fragen zu Ablauf, Inhalt und Schwerpunkten stehen wir gerne auch persönlich im Vorfeld zu ihrer Verfügung.

READ MORE

READ MORE

ERMÄßIGTER EINTRITTSBON

North Sails auf der Boot Tulln 1. 3. - 4. 3. 2018 in Halle 4/419

READ MORE

READ MORE

ERMÄßIGTER EINTRITTSBON

North Sails auf der Boot Tulln 1. 3. - 4. 3. 2018 in Halle 4/419

Download deinen Ermäßigungsbon und besuche unsere täglichen North Events ab 16.00 Uhr in Halle 4/419

READ MORE

READ MORE

AWAY TO THE RACES

AWAY TO THE RACES

Kicking off the 2018 year with the Toronto International Boat Show

This year marked the 60 th Anniversary of the Toronto Boat Show – quite the milestone for organizers. Each year has its own specialities and focus. For 2018 and our Toronto loft, the focus was on 3Di Nordac which many customers were eagerly interested in knowing more. The NEW product for 2018 has garnered widespread interest and support, specifically among cruisers. Torontonians were no exception. Our local North Sails experts Geoff Moore, Louisa Sonosky, Miro Balcar, Mike Wolfs and Hugh Baeton were on site throughout the show to answer any questions regarding 3Di Nordac and all North Sails products. Additionally, Hugh Beaton and Mike Wolfs were on-hand to share their North Sails stories.

https://www.youtube.com/watch?v=7VVd9kf797w&index=4&list=PL3EYJa84RjjlT3EZMHCmft8wvCRMit65D

A busy show it was throughout the 10 days with familiar faces and new; thank you to everyone who stopped by!

If you have questions regarding a quote you received at the show, products or materials please reach out to any of our local North Sails experts.

Hear our team talk about their expertise in sailmaking and service. See you on the race course!

https://youtu.be/7VVd9kf797w

READ MORE

READ MORE

NORTH SAILS AUSTRIA AUF DER BOOT TULLN 2018

CHEERS,

Die Limited Edition North Sails Bier zur Happy Hour auf der Boot Tulln 2018 täglich ab 17.00 Uhr bei North Sails Austria Halle 4 / Stand 419 solange der Vorrat reicht.

Plopp, so einfach gehts: Gutschein vollständig ausfüllen und bei der Happy Hour abgeben oder bis zum 01.03.2018 an office.at@northsails.com senden.

Trimm mit,

bei unserem kostenlosen Trimmvortrag, der North University, welcher auf der neuen Kielversion der Lago26 von Hans Spitzauer täglich um 16.00 Uhr am North Stand gehalten wird.

Staunen und Angreifen,

das raffinierteres "Dacron"-Fahrtensegel- mit 3Di-Technologie nur bei North Sails erhältlich.

Das 3Di NORDAC ist ein revolutionäres Produkt, welches das Dacron Fahrtensegel neu erfindet. 3Di NORDAC kombiniert die einzigartigen Eigenschaften von 3Di-Verbundsegeln mit altbekannter Polyesterfaser. Das Resultat ist ein innovatives Fahrtensegel mit einer noch geschmeidigeren und beständigeren Aerodynamik für bessere Kontrolle, mehr Komfort und höhere Performance. North Sails fertigt schon seit Jahren tausende 3Di- Segel, die Millionen von Seemeilen zurückgelegt haben. 3Di-Segel bestehen aus ultradünnen, gleichlaufenden Faser Tapes, die mit duroplastischem Harz vorimprägniert sind. Mit dem North-eigenen, computergesteuertem Tape-Legesystem werden die Segelmembranen mit einer hoch komplexen Faseranordnung versehen. Die 3Di-Segel werden dann über einer frei konfigurierbaren 3D-Form in einem Stück als Membran thermogefertigt. Im Gegensatz zum konventionellen Weben und Nähen von einzelnen Segeltuchbahnen verwendet die 3Di Technologie eine monolithische Konstruktionsweise, wie sie schon seit Jahrzehnten bei Yachten aus Glasfaser und Verbundmaterial Verwendung findet. 3Di NORDAC ist die moderne Lösung bei der Suche nach höchstem Cruising-Vergnügen und bester Performance.

STARK – GESCHMEIDIG - NAHTLOS

100% Polyester für unerreichte Haltbarkeit.

Weiße Oberfläche mit ausgezeichneter Reiß- und Verschleißfestigkeit

3D-geformte Verbundkonstruktion aus einem Stück

Variable Faserdichte und -ausrichtung für optimales Verhältnis von Material und Belastung

Integrierte Lattentaschen,Eckverstärkungen und Reffpunkte

Hervorragende UVBeständigkeit Einsatzgebiete

Speziell für kleine bis mittelgroße Fahrtenyachten mit einer Vorliekslänge bis 16m entwickelt

Wir freuen uns auf Ihren Besuch!

Andrea Seidl, Hans Spitzauer, Ernst Seidl

Ihr North Sails Messeteam

READ MORE

READ MORE

NORTH SAILS AUSTRIA AUF DER BOOT TULLN 2018

CHEERS,

Die Limited Edition North Sails Bier zur Happy Hour auf der Boot Tulln 2018 täglich ab 17.00 Uhr bei North Sails Austria Halle 4 / Stand 419 solange der Vorrat reicht.

Plopp, so einfach gehts: Gutschein vollständig ausfüllen und bei der Happy Hour abgeben oder bis zum 01.03.2018 an office.at@northsails.com senden.

Trimm mit,

bei unserem kostenlosen Trimmvortrag, der North University, welcher auf der neuen Kielversion der Lago26 von Hans Spitzauer täglich um 16.00 Uhr am North Stand gehalten wird.

Staunen und Angreifen,

das raffinierteres "Dacron"-Fahrtensegel- mit 3Di-Technologie nur bei North Sails erhältlich.

Das 3Di NORDAC ist ein revolutionäres Produkt, welches das Dacron Fahrtensegel neu erfindet. 3Di NORDAC kombiniert die einzigartigen Eigenschaften von 3Di-Verbundsegeln mit altbekannter Polyesterfaser. Das Resultat ist ein innovatives Fahrtensegel mit einer noch geschmeidigeren und beständigeren Aerodynamik für bessere Kontrolle, mehr Komfort und höhere Performance. North Sails fertigt schon seit Jahren tausende 3Di- Segel, die Millionen von Seemeilen zurückgelegt haben. 3Di-Segel bestehen aus ultradünnen, gleichlaufenden Faser Tapes, die mit duroplastischem Harz vorimprägniert sind. Mit dem North-eigenen, computergesteuertem Tape-Legesystem werden die Segelmembranen mit einer hoch komplexen Faseranordnung versehen. Die 3Di-Segel werden dann über einer frei konfigurierbaren 3D-Form in einem Stück als Membran thermogefertigt. Im Gegensatz zum konventionellen Weben und Nähen von einzelnen Segeltuchbahnen verwendet die 3Di Technologie eine monolithische Konstruktionsweise, wie sie schon seit Jahrzehnten bei Yachten aus Glasfaser und Verbundmaterial Verwendung findet. 3Di NORDAC ist die moderne Lösung bei der Suche nach höchstem Cruising-Vergnügen und bester Performance.

STARK – GESCHMEIDIG - NAHTLOS

100% Polyester für unerreichte Haltbarkeit.

Weiße Oberfläche mit ausgezeichneter Reiß- und Verschleißfestigkeit

3D-geformte Verbundkonstruktion aus einem Stück

Variable Faserdichte und -ausrichtung für optimales Verhältnis von Material und Belastung

Integrierte Lattentaschen,Eckverstärkungen und Reffpunkte

Hervorragende UVBeständigkeit Einsatzgebiete

Speziell für kleine bis mittelgroße Fahrtenyachten mit einer Vorliekslänge bis 16m entwickelt

Wir freuen uns auf Ihren Besuch!

Andrea Seidl, Hans Spitzauer, Ernst Seidl

Ihr North Sails Messeteam

READ MORE

READ MORE

PRIMEIRA CLÍNICA DE 2018, COM HUGO ROCHA, CONTOU ONZE EQUIPAS DE 420

Primeira Clínica de 2018, com Hugo Rocha, contou Onze Equipas de 420

2018 arranca com a realização da nossa Primeira Clínica do ano para a Classe de 420. Durante dois dias, 11 Equipas tiveram a oportunidade de partilhar experiências com o nosso Class Expert, Hugo Rocha. Velejadores do CVBarreiro, CNCascais, CVLagos, CNSesimbra e CIMAV aderiram com grande entusiasmo a esta iniciativa.

Na sequência do trabalho realizado em Cascais, continuamos a apoiar os velejadores durante a presente época. Para participarem nesta actividade as equipas anteciparam a sua chegada a Vilamoura, onde vai já amanhã começar o Torneio de Carnaval e onde será, no próximo ano, o palco do Campeonato Mundial da Classe 420.

Fomos recebidos pelo CIMAV que nos disponibilizou as suas instalações, dando assim o seu contributo para o operacionalização desta Clínica e para a viabilização de mais um momento importante no percurso destes velejadores.

O primeiro dia ficou marcado por uma grande variação de ventos, contexto do qual conseguimos extrair várias situações-tipo para treinar diferentes cenários e utilizá-los como temas para reflexões em grupo.

O segundo dia, por falta de vento, foi mais dedicado a uma abordagem teórica que se tornou num momento muito interessante, onde velejadores e treinadores se juntaram para partilhar dúvidas, dicas e experiências com o apoio do Hugo Rocha.

Agradecemos a todas as Equipas a sua participação e empenho na partilha de experiências, ao CIMAV todo o apoio local que nos disponibilizou e aos Hotéis Dom Pedro as condições que proporcionou. O nosso obrigado também à Ingrid Braga Fortunado pelas fotografias que disponibilizou.

Terminámos com um balanço positivo!l Velejadores saíram da Clínica com novas aprendizagens e aproveitaram a oportunidade para aprender que são várias as opções existentes, o que podem agora colocar em prática!

Se tens interesse nas Clínicas North Sails não deixes de nos contactar!

READ MORE

READ MORE

LAS VELAS 3Di, A EXAMEN EN EL MUSEO VOLVO OCEAN RACE

LAS VELAS 3Di, A EXAMEN EN EL MUSEO VOLVO OCEAN RACE

Luis Martínez Doreste y Nacho Braquehais protagonizaron una charla sobre las velas 3Di que equipan los barcos de la Volvo Ocean Race. El evento, celebrado en el Museo Volvo Ocean Race de Alicante, contó con una nutrida participación de público y fue retransmitido por Internet.

Luis Martínez Doreste y Nacho Braquehais explicaron cómo se fabrican las velas North Sails 3Di y repasaron el inventario a bordo de los Volvo Ocean 65 que participan en la Volvo Ocean Race 2017-18. El acto llenó la sala de conferencias del Museo Volvo Ocean Race de Alicante y fue retransmitida en directo a través de Internet.

El vídeo está disponible aquí.

North Sails es el proveedor oficial de velas de la Volvo Ocean Race 2017-18.

READ MORE

READ MORE

LAS VELAS 3Di, A EXAMEN EN EL MUSEO VOLVO OCEAN RACE

LAS VELAS 3Di, A EXAMEN EN EL MUSEO VOLVO OCEAN RACE

Luis Martínez Doreste y Nacho Braquehais protagonizaron una charla sobre las velas 3Di que equipan los barcos de la Volvo Ocean Race. El evento, celebrado en el Museo Volvo Ocean Race de Alicante, contó con una nutrida participación de público y fue retransmitido por Internet.

Luis Martínez Doreste y Nacho Braquehais explicaron cómo se fabrican las velas North Sails 3Di y repasaron el inventario a bordo de los Volvo Ocean 65 que participan en la Volvo Ocean Race 2017-18. El acto llenó la sala de conferencias del Museo Volvo Ocean Race de Alicante y fue retransmitida en directo a través de Internet.

El vídeo está disponible aquí.

North Sails es el proveedor oficial de velas de la Volvo Ocean Race 2017-18.

READ MORE

READ MORE

NORTH SAILS ÖVERGÅNG FRÅN 3DL TILL 3Di ÄR NU HELT GENOMFÖRD

NORTH SAILS ÖVERGÅNG FRÅN 3DL TILL 3Di ÄR NU HELT GENOMFÖRD

Ökad produktionskapacitet i Minden (Nevada) och Sri Lanka med fokus på 3Di-segel till mindre båtar

I januari 2018 passerade North Sails ytterligare en historisk milstolpe. Då var nämligen skiftet från membransegel till kompositsegel – eller från 3DL till 3Di – som pågått under nästan tio år helt genomfört.

3DL-seglen var banbrytande när de lanserades i början av 1990-talet. Sedan dess har de haft en dominerande ställning inom segmentet fiberförstärkta mylarsegel, och det krävdes en helt ny North-produkt för att rubba dess ställning. De första prototyperna till det som idag är 3Di testades under Americas Cup 2007 när North byggde ett antal kompositsegel helt utan film till titelförsvaren Alinghi. Sedan dess har 3Di-konceptet vidareutvecklats och används nu på alla typer av båtar, från extrema kappseglingsbåtar och superyachts till långfärdsbåtar.

Dagens 3Di-segel håller formen bättre och har en överlägsen livslängd jämfört med alla typer av mylarbaserade membransegel, inklusive våra egna 3DL-segel. Intresset för 3Di har ökat stadigt sedan säljstarten 2010, och i och med lanseringen av 3Di RAW 760S och 3Di NORDAC har vi nu 3Di-produkter som är perfekt anpassade även för mindre kappseglingsbåtar och mindre cruisingbåtar. För att kunna möta den ökade efterfrågan har North Sails nu vidtagit en rad åtgärder för att öka produktionskapaciteten av 3Di-segel.

I takt med utfasningen av 3DL-tekniken har North Sails genomfört omfattande anpassningar av fabrikerna i Minden, Nevada och Sri Lanka. I september 2017 stängdes den sista 3DL-linjen ner och båda fabrikerna tillverkar nu enbart 3Di-segel.

Samtidigt har produktionskapaciteten höjts. Som exempel kan nämnas att den så kallade ATL-processen (Automated Tape Laying), där seglet byggs upp genom att prepreg-behandlade fibertejper läggs upp enligt ett noga specificerat mönster, nu sker 24 timmar om dygnet, sju dagar i veckan, på sju produktionslinjer i Minden och fem i Sri Lanka. Konverteringen av prepreg-strukturen sker med bakning under värme och tryck på totalt tio justerbara 3D-formar.

© Ben Zucker

Dan Neri, North Sails CEO, förklarar bakgrunden till företagets ändrade produktionsstrategi: "Utbyggnaden av fabriken i Sri Lanka är ett svar på de lyckade lanseringarna av 3Di RAW 760S och 3Di Nordac, som är speciellt utvecklade för att passa mindre kappseglingsbåtar respektive mindre cruisingbåtar. I och med detta har vi nu ett 3Di-sortiment som uppfyller alla de krav som kräsna seglare ställer, oavsett om det handlar om en 18 fots skiff eller en 100-fots superyacht. 3Di-teknologin ligger bakom ett oräkneligt antal regattavinster och världsrekord, och vi ser fram emot att få höra om de äventyr som möjliggörs nu när 3Di Nordac snabbt vinner mark bland cruisingseglare."