A GRAND PRIX YEAR IN FULL EFFECT

In a year defined by maxed‑out production and successes on and off the water, North Sails quietly proved it’s no longer just a sailmaker—it’s the performance partner behind Grand Prix sailing’s biggest wins.

There is an old joke one might hear around the North Sails water cooler, the one about how to spell the word “fun.” The answer is “W.I.N.,” of course, and while there was plenty of winning for North Sails customers around the world, for Paul Westlake, Grand Prix Sales Leader, the real answer goes well beyond the pride that customers feel at the podium.

“Winning, to North Sails, is finding that perfect balance of performance, enjoyment and turnkey technology for our customer base,” he says. “While the Grand Prix arena brings a distinct set of expectations, we dedicate significant effort to understanding and meeting the unique needs of each team we partner with.”

Those programs included a dominant share across the RORC’s reborn Admiral’s Cup fleet, including the overall winning two-boat team representing the Yacht Club de Monaco. Add the RC44 World Champions to the list of satisfied customers, as well as the entirety of the ClubSwan One Design World Championship classes, the GL52s and TP52s, the Rolex IMA Grand Prix World Champions, and the best of the IMOCA fleet. For North Sails, 2025 was indeed a good year.

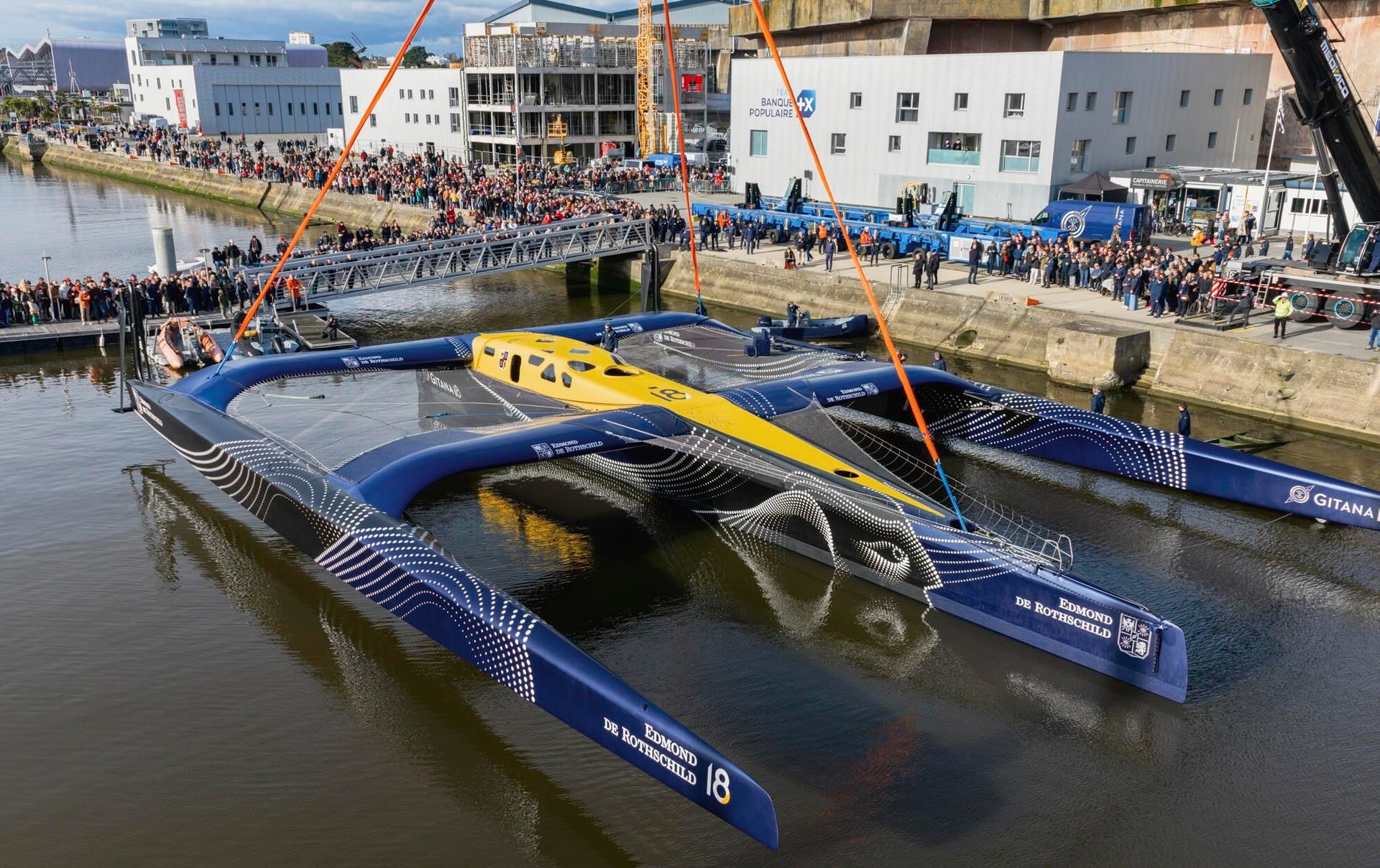

📸: North Sails / Atila Madrona

“To have that sort of domination in Grand Prix racing doesn’t happen by chance,” Westlake says. “For teams that make the commitment to North Sails, we make the mutual commitment back. Everything we do is about giving them a turnkey performance – helping them find their version of the podium, whatever that looks like for their program.”

From who makes the material, to who designs, models, builds, and supports the entire performance system, every North Sail partnership exists in three dimensions. There’s innovation through the North Design Suite, Helix structured luff, 3Di composites, and soon there will be ultra-high-modulus carbon and advanced downwind fabrics baked into every Grand Prix inventory. There’s experience, with dozens of designers and engineers, many of whom also race at the very top level, and the ability for North personnel to integrate rating-rule strategies, class rules, inventory planning, and day-to-day boat handling.

In this regard, Westlake likes to quote North’s crew boss Ken Read. “He has said many times that there’s four jobs at North Sails—we sell them, we design them, we build them and we use them.”

There’s also the North Sails global network, from Sri Lanka’s bustling production floors to local lofts and on-water coaches, to marketing and media teams amplifying the stories. Every one of North’s nearly 2,000 employees has a stake in the results. Winning, in this context, isn’t just standing at the top of the podium. As North Sails likes to frame it, every team has its own podium—whether that’s first overall, breaking into the top six, or simply making a meaningful jump up the fleet. The job is to help each client reach their version of winning.

📸: The 44 Cup / Nico Martinez

DELIVERING TO ADMIRAL’S CUP DEMANDS

This philosophy was on full display at this summer’s Admiral’s Cup, an astonishing gathering of international teams. The rebirth of this unique regatta was a proving ground for race teams and sail inventories alike. The event exceeded expectations, and owners went all in, Westlake says, and the performance bar for offshore Grand Prix jumped dramatically. North Sails responded by delivering 230-plus fully custom sails for Admiral’s Cup teams—on top of the normal spring crunch.

North’s Admiral’s Cup efforts tapped all capabilities of North Sails, including two dozen designers from a 61-strong global design and engineering group with the Yacht Club de Monaco’s winning effort serving as a prime example. Westlake says Monaco’s two-boat Jolt program put a greater emphasis on windward-leeward type performance, “because they really settled on the fact that if they were going to win the Admiral’s Cup they had to be the very best in VMG upwind and VMG downwind, and then they separately dealt with their reaching inventory.”

That meant their core inventory of mainsails and jibs were optimized for straight-line performance, and working with North, they then built a dedicated reaching package—masthead zeros and blast-reaching sails—designed around the realities of the Admiral’s Cup course and sail-number limits. North designers and Jolt’s sailing team spent a lot of time on the water, refining how and when to use those reaching sails, treating them as a specialist tool rather than a compromise. The impact, as Westlake tells it, is that every piece of Jolt’s configuration—boat setup, sail plan, and reaching inventory—was tuned to a deliberate strategy, with North acting as a partner in executing that strategy rather than just supplying a standard TP52 set of sails.

Across the Admiral’s Cup fleet of diverse designs, Westlake adds, each program ran with unique inventories. “There was no copy-paste, no standard package for anyone,” Westlake says. “Every sail was custom to that owner’s rating strategy, targets, and expectations.”

For North, the Admiral’s Cup was a breakout year for free-flying reaching sails where the modern masthead Code Zero evolved into a family of zeros for light upwind angles and heavy-air blast reaching, all thanks to North’s Helix structured luff and 3Di composite engineering, which allows these lighter sails to be used across a much wider wind range. The scope of refined sail designs, visible across the Solent on any given day, reflects North Sails’ unrivaled capabilities, which start at the North Design Suite, using virtual wind-tunnel CFD to model flying shapes, loads, and driving forces before a sail is ever built. Wrapped in advanced sail crossover and load models—tying sails to rig, foils, and safety margins—the results are far more today than a set of sails delivered in blue bags.

📸: Alea / Jean-Louis Carli

AMERICA’S CUP AND THE DESIGN SUITE DRIP

In 2025, the America’s Cup “trickle-down” went from being a cliché to becoming visible in results. The same North Design Suite tools—licensed and refined inside each of the Cup teams—and the composite technology used to engineer twin-skin mainsails for the AC75s, were driving TP52, ClubSwan, and offshore-racing inventories—shaping everything from lower-aspect mainsails to highly specialized masthead zeros. Whether they realized it or not, owners weren’t getting rebadged Cup technology; they were racing with Cup-developed software, structures, and load models embedded in every sail. With AC38 just around the corner, Westlake says, the tools are only getting better: “It keeps evolving with every Cup cycle -- it’s never frozen.”

While it’s easy to attribute North Sails’ latest Grand Prix successes to advance sail design and the physical above deck components, Westlake reminds us that success is everything that touches a program. North measures itself not only on results and market share, but on participation and the overall health of the sport. That means a commitment to having coaches and designers on the water, real-time support, and a global communication effort that amplifies customers’ stories.

“Our support goes beyond delivering the best sails we possibly can to our customers, it’s not just dropping them on the dock, patting them on the back and saying, ‘Good luck, hope you hit the first shift,’ and waving goodbye,” Westlake says. “We have an on-the-water presence and incredible marketing support. We now can confidently say we touch a million people a month through the web and social media, so we have a responsibility to give back to the sport, to show how supercool it is.”

For the good of the sport, perception does matter, Westlake adds. The goal isn’t just to win regattas; it’s to grow participation. When aspirational sailors see modern TP52s and one-designs, AC40s, Moths and offshore racing programs presented in a compelling way, they’re more likely to get on the water—at any level and at any age.

📸: 52 Super Series

GRAND-PRIX SUCCESS DRIVES INNOVATION

Looking forward, Westlake acknowledges the continuation of clear trends that emerged in 2025. Foremost among them is that, “Helix is everywhere.” It has moved from a niche buzzword to a core engineering principle, he says. “Every 3Di Grand Prix sail now leverages structured luff thinking for better shape control and wider range, upwind and down,” he says. “That means we’re no longer talking exclusively about upwind and downwind sail development. Reaching sails are now a discipline of their own.

But what has Westlake especially excited is what’s coming next in downwind sails. He teases a new fabric technology, engineered specifically for modern Grand Prix boats that sail at low apparent wind angles and reaching sails. Designed with the Helix mindset, which means lighter and stronger masthead zeros and kites with broader wind ranges without sacrificing control. “That’s going to be a cool spring story the world is going to wake up to,” he says. “The Helix evolution never stops.”

What’s also on deck is the rollout of 3Di RAW 900, an aerospace-grade carbon developed with Emirates Team New Zealand for the America’s Cup. The promise of RAW 900 for mainsails and headsails is its ability to handle greater loads, lock in flying shapes more precisely across an expanded wind range. For owners and trimmers, this means more stability, more repeatability, and the ability to push harder without compromising the sail’s long-term shape.

It’s safe to say that for the entirety of 2025, North Sails didn’t just win regattas with the sport’s top Grand Prix programs. It validated a model where, when teams choose North, they’re not only buying sails, they’re aligning with a performance partner that delivers innovation, experience, and a global team fully committed to the cause.