LONGEST-LASTING

Mylar film is a versatile material with many uses; performance sails aren't one of them. North Sails' zero Mylar 3Di construction method creates exceptionally durable sails that resist stretching, UV degradation, and, most importantly delamination.

Because of zero Mylar construction, 3Di sails boast enduring shape retention and withstand harsh weather. This ensures consistent, top-tier performance throughout the sail's lifespan.

Mylar film is a versatile material with many uses; performance sails aren't one of them. North Sails' zero Mylar 3Di construction method creates exceptionally durable sails that resist stretching, UV degradation, and, most importantly delamination.

Because of zero Mylar construction, 3Di sails boast enduring shape retention and withstand harsh weather. This ensures consistent, top-tier performance throughout the sail's lifespan.

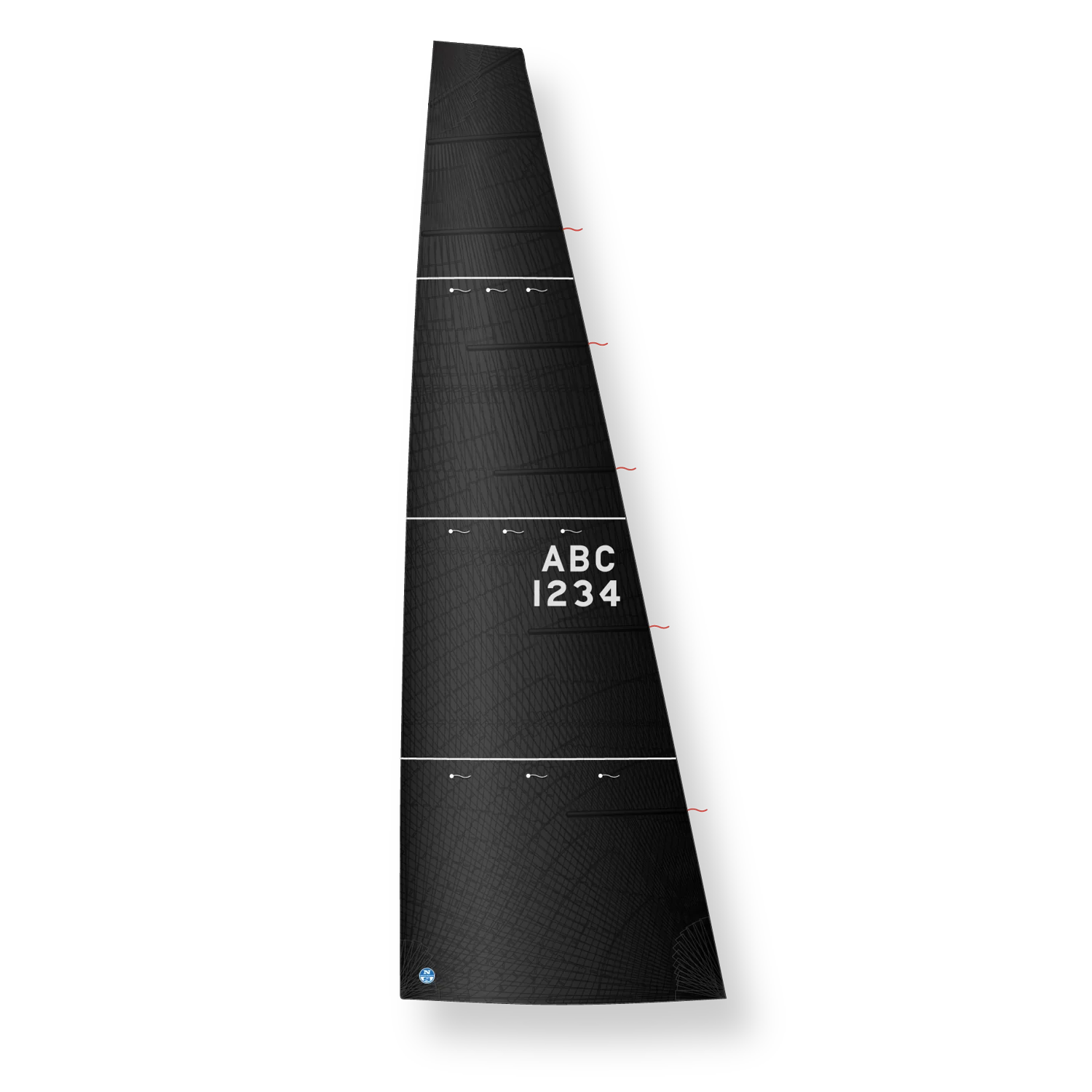

AERO-OPTIMIZED

A streamlined sail shape delivers less drag, more drive, and greater effectiveness across a wider wind range.

North Sails designers pair our bespoke computer software and analytics with full-sized 3D molds to precisely match ideal aerodynamic shapes to all types of boats. The smooth, one-piece sails are more durable and resistant to stretch. The effective lifespan of a 3Di sail is considerably longer than the competition.

A streamlined sail shape delivers less drag, more drive, and greater effectiveness across a wider wind range.

North Sails designers pair our bespoke computer software and analytics with full-sized 3D molds to precisely match ideal aerodynamic shapes to all types of boats. The smooth, one-piece sails are more durable and resistant to stretch. The effective lifespan of a 3Di sail is considerably longer than the competition.

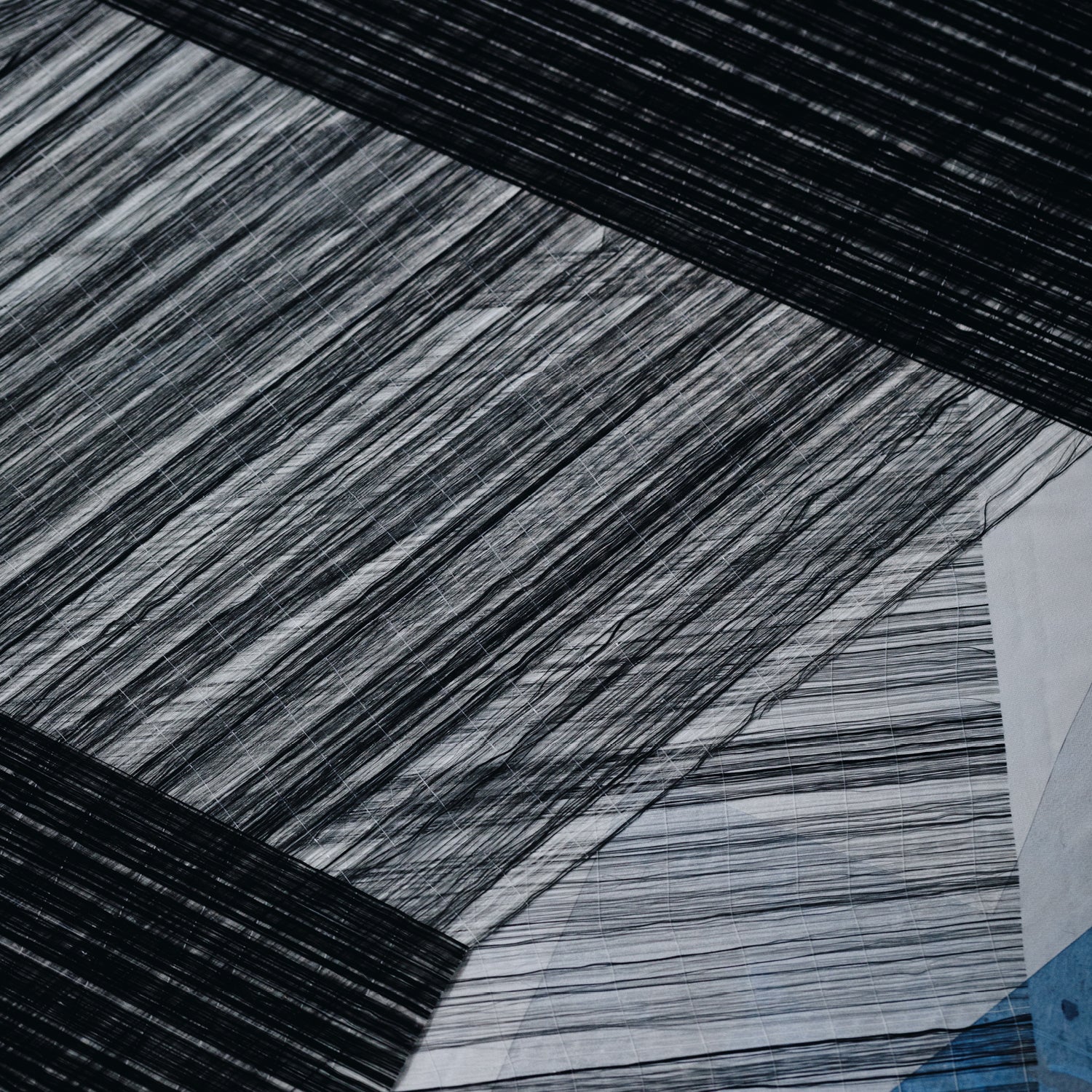

LIGHTER + STRONGER

If another sailmaker tells you they can make a sail lighter and stronger than 3Di - that is impossible.

3Di sail structure starts with the world's lightest, strongest, most durable filaments, less than the width of a human hair. This allows North designers to engineer the sails 20% lighter for equal strength or 20% stronger for equal weight compared to any competing sail on the market. With zero Mylar construction, every ounce of a 3Di sail's structure goes towards performance.

If another sailmaker tells you they can make a sail lighter and stronger than 3Di - that is impossible.

3Di sail structure starts with the world's lightest, strongest, most durable filaments, less than the width of a human hair. This allows North designers to engineer the sails 20% lighter for equal strength or 20% stronger for equal weight compared to any competing sail on the market. With zero Mylar construction, every ounce of a 3Di sail's structure goes towards performance.

3Di TECHNOLOGY

INSIDE 3Di

MATERIAL GUIDE

EXPLORE 3Di USE GROUPS

- Refresh page

CUSTOMER TESTIMONIALS

3Di is an amazing product for racing sails, truly the best technology available. North 3Di sails are extremely strong and built with precise, refined sail shapes. I recommend North Sails and 3Di because they are the best sails, created by the best designers.

PIERLUIGI DE FELICE

GRAND PRIX SAIL TRIMMER

REQUEST A QUOTE

REQUEST A QUOTE

CUSTOMER TESTIMONIALS

We chose North 3Di because a versatile inventory and longevity were crucial factors for Miss Shell. Since her launch in 2022,Miss Shell has sailed more than 15,000 miles! The 3Di sails have lived up to their promise with only two routine maintenance appointments. Whether we're crossing the Atlantic, exploring the Med, or sailing in New England, North 3Di is our choice and recommendation to other sailors.

ERIC LEINER

OWNER, MISS SHELL

REQUEST A QUOTE

REQUEST A QUOTE

CUSTOMER TESTIMONIALS

We sail really hard, so it´s important to have strong sails; reliable but good performance. The sails are what makes the boat go fast.

CHARLES DALIN

IMOCA SKIPPER

REQUEST A QUOTE

REQUEST A QUOTE