SAILING IS BETTER IN 3D

THE NEED FOR SOMETHING BETTER

North Sails pioneered 3D sailmaking in 1990 with a secret sail development program under a tight lid of security. The goal was to develop a radical new sail that was lighter, stronger, and faster than anything before. It was named 3DL.

At the 1993 Key West Race Week event, with fingers crossed, North equipped seven boats with the new 3DL sails. In their April ‘93 issue, Yachting Magazine reported: “Seven boats at Key West…carried sails made with North’s new 3DL. Two won their classes, and only one placed lower than fourth. Those results speak more for the boats and their crews than the contributions of a single sail. But there’s no getting around the fact that 3DL was a common thread.”

One year later, a more thoroughly developed 3DL returned to Key West and dominated one of the largest and most competitive international racing fleets ever assembled. The results were unequivocal, and a deluge of 3DL sail orders produced a backlog that lasted two years. 3DL is the start of the North Sails 3D sailmaking story.

WHAT'S THE DIFFERENCE?

3Di vs. PANELED SAILS

Anything that’s not 3Di is a paneled sail. Paneled sails are put together on a flat 2D surface and shaped through broad seaming; the edges of each panel are tapered to be narrower at the edges than in the middle and then seamed to the next panel, creating depth. Paneled sails include everything from a woven Dacron sail to a string sail made from materials like carbon and Mylar.

Anything that’s not 3Di is a paneled sail. Paneled sails are put together on a flat 2D surface and shaped through broad seaming; the edges of each panel are tapered to be narrower at the edges than in the middle and then seamed to the next panel, creating depth. Paneled sails include everything from a woven Dacron sail to a string sail made from materials like carbon and Mylar.

North Sails took a chance on the 3Di concept for sail construction in 2010 years. At that time, 3DL was the undisputed state-of-the-art in high-performance sailmaking. 3DL sails were powering the winning boats in the America’s Cup, the Volvo Ocean Race, most inshore Grand Prix, and countless local race boats. However, while our customers were generally happy with The 3DL product, our designers and salespeople knew that the product’s durability needed to be improved. In the best examples, the sails didn’t last long enough to deliver the value we wanted for our customers. In the worst examples, the sails delaminated prematurely, leaving the boat owners with a rattly mess of Mylar film and loose yarns. It was not obvious that 3Di would be good enough to replace 3DL, but it was obvious that we had to try it.

The early 3Di sail concept was brought to North Sails by the inventors Gerard Gautier and Eduard Kessi in the form of “Amalgam” sails. The components of the Amalgam product were spread filament tapes made up of resin and PBO material, flat panels with sail shape introduced via an adjustable broadseaming fixture, and tape mapping determined using the Relax FEA software. Over the first few years of working with Gerard, the North Sails designers and engineers changed every one of those components, retaining only the concept of spreading fibers into filaments.

ALL IN ON 3Di

In 2018, North Sails completed a 10-year transformation and retired 3DL string laminates in favor 3Di molded composite sail structures. With the shift to 3Di, the North Sails ceased production of laminated sails reliant on mylar and fully committed to the spread filament, prepreg, 3D composite structures. Three-dimensional, full-scale shape molding remains a cornerstone of the North Sails approach.

In 2018, North Sails completed a 10-year transformation and retired 3DL string laminates in favor 3Di molded composite sail structures. With the shift to 3Di, the North Sails ceased production of laminated sails reliant on mylar and fully committed to the spread filament, prepreg, 3D composite structures. Three-dimensional, full-scale shape molding remains a cornerstone of the North Sails approach.

Today, 3Di sailmaking has evolved into a sophisticated system for engineering a sail’s structure tailored to the boat’s precise requirements, rig, and anticipated operating environment. Our sail designers select tapes from a library of fiber types, hybrid styles, and weights and apply those materials to a taping map which dictates how the sail behaves under sailing loads. The material selections and taping map are the building blocks of the structure, and the unique 3-dimensional molding process imparts the static shape to that structure. The North Design Suite modeling delivers the information the designer needs to engineer the dynamic changes to the flying shape as the sailor moves through the range of controls on board.

SCIENTIFIC SAILMAKING

It is possible to make a pretty good sail with a seat-of-the-pants approach. Plenty of great sailors worldwide have a grasp of broadseaming and luff curve with a natural eye for good sail shape. Through trial and error, use of commercially available materials, off-the-shelf software, and lots of input from those gifted sailors, the “by sailors, for sailors” approach has worked for most sailmakers for many decades. But that approach would be a disaster for the 3Di production system.

3Di is based first and foremost on a scientific approach to understanding the properties of all fiber types available to us. Those properties change when the fiber is spread into filament level and when two or more fiber types are co-mingled into the same prepreg tape. In all cases, those properties change again when the material is stacked into a composite structure and subjected to fatigue factors like flogging, folding, flexing, and environmental exposure. Unfortunately, data supplied by the fiber manufacturers is often misleading; their testing methods are irrelevant for sail use cases or, in many cases, because they don’t understand how their fibers behave on the water.

North Sails is unique among our sailmaking competitors in our understanding of material properties after fatigue because we test in-house and study continuously. With this understanding, we manufacture bespoke materials by combining fiber types into spread filament prepreg tapes with a wide range of controlled tensile, modulus, and elasticity characteristics.

OVERALL BENEFITS OF A 3Di SAIL

Due to the unique sail construction of 3Di, the sail does not distort under high loads and the spread filament tape layers provide increased longevity and minimize stretch, which resists damage from UV, chafe, abrasion and flex. 3Di sails last longer than any paneled sail on the market. And unlike mylar, 3Di sails will not delaminate, ever.

Due to the unique sail construction of 3Di, the sail does not distort under high loads and the spread filament tape layers provide increased longevity and minimize stretch, which resists damage from UV, chafe, abrasion and flex. 3Di sails last longer than any paneled sail on the market. And unlike mylar, 3Di sails will not delaminate, ever.

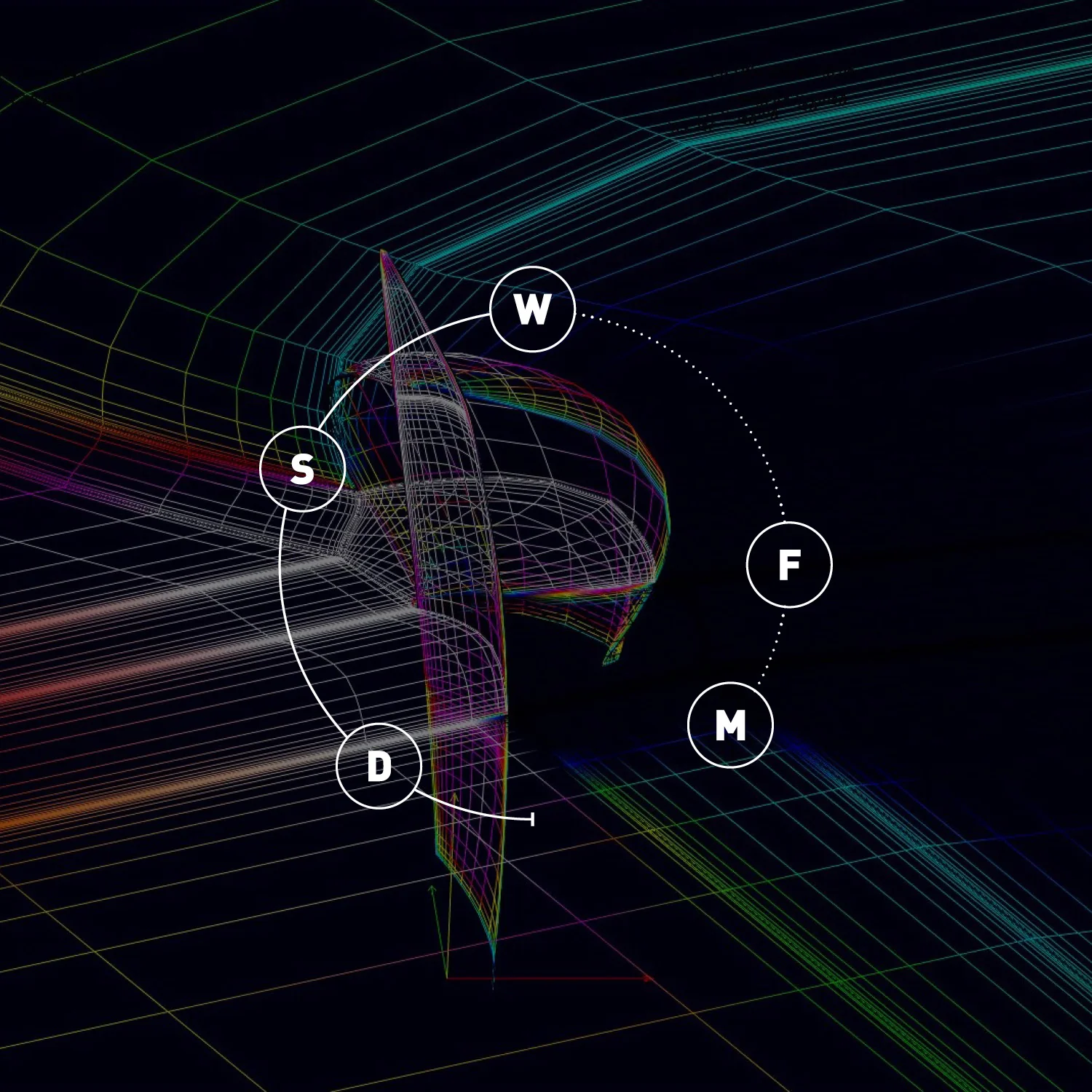

BETTER BY DESIGN

North sail designers sit at the controls of the entire 3Di process. They have the most powerful suite of aerodynamic and structural analysis tools in the world. It is no coincidence that every America’s Cup syndicate competing in the 37th Cup has leased the North Design Suite (NDS) to provide aero data to their engineering teams. NDS is loaded with a library of 3Di tapes and another library of tape layout solutions. When a tape style is selected and applied to a layout, that tape’s properties and orientation dictate the sail surface’s behavior. For example, the sail designer can choose a tape with an extremely high modulus and a layout with a direct mapping of the load direction, resulting in an area of the sail that does not change regardless of the load applied. For another area of the sail, the designer can apply a tape with a much higher elasticity and orient the tapes, so they are at angles to the load direction; that part of the sail will stretch under load. Every element of the sail will behave in a way determined by the materials stacked up with that space, and the mosaic of all those elements determines the flying sail shape. The sail designer can dial in the shape and depth of the sail through the range of aero loading and control line tension using the power of NDS and the properties of the 3Di materials.