WHEN TO REPLACE YOUR SPINNAKER

North Sails expert Tom Davis takes a close look at spinnaker sailcloth to explain how to use all your senses to answer this question for yourself.

What to look for and how to prolong the life of the material

Remember when your spinnaker was new—how crisp and clean the material felt and the way it crinkled going into the bag? The whites were white and the colors were bright, and it even smelled like the brand new nylon that it was. When it filled and snapped in the breeze, you knew it was pulling your boat forward for all it was worth. Your senses knew that your sail was new, and if you allow them, they’ll help you understand when that same spinnaker is ready for replacement.

All your sails are like the four tires on your car. When you use them, they will wear out – eventually. Like anything that wears out from use, it is good to learn the ways you can prolong the product’s lifespan and know when it’s time for replacement. Of all the sails, the spinnaker is the trickiest sail to evaluate, but remember to let your senses help.

Looking at spinnaker cloth through a microscope

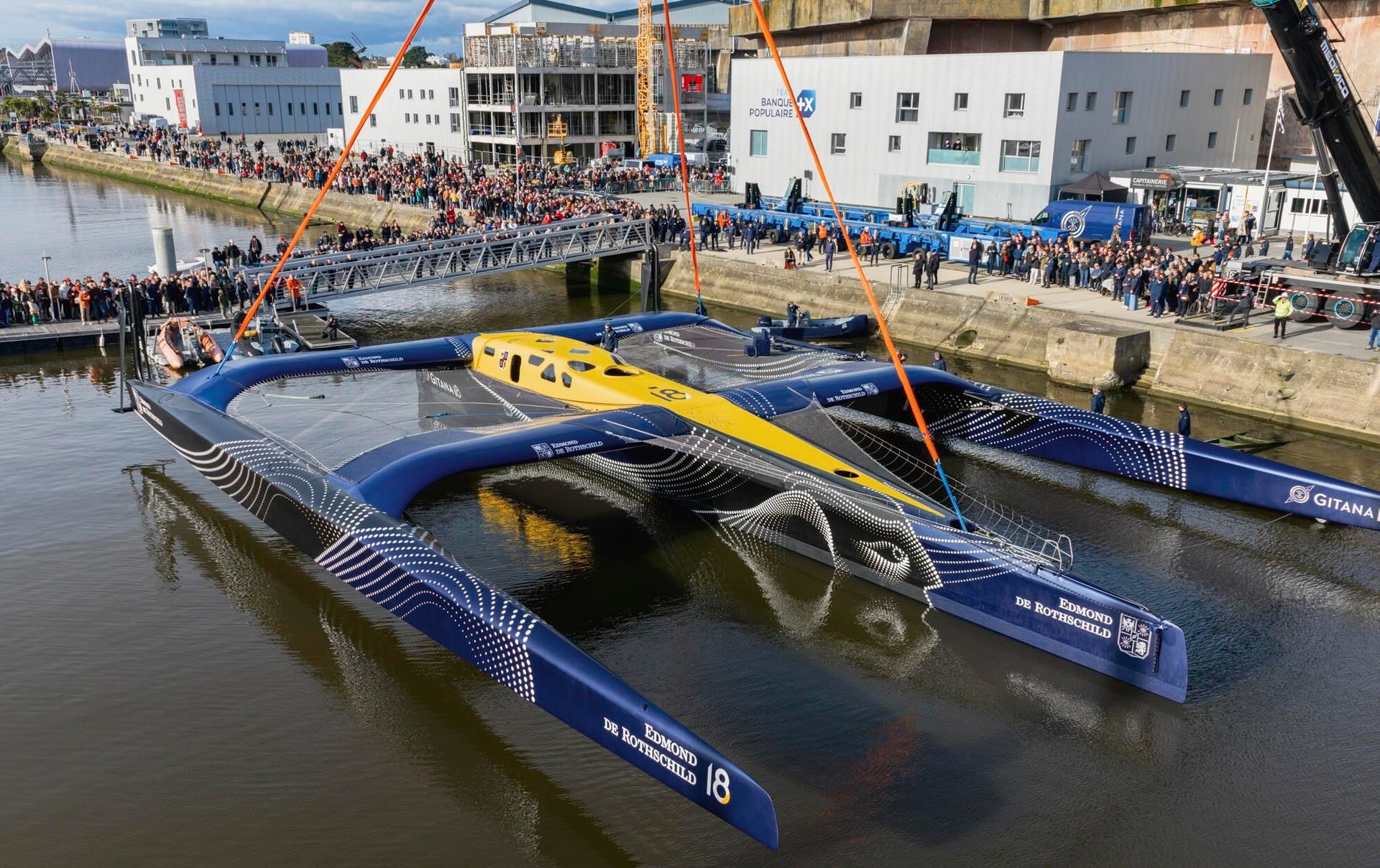

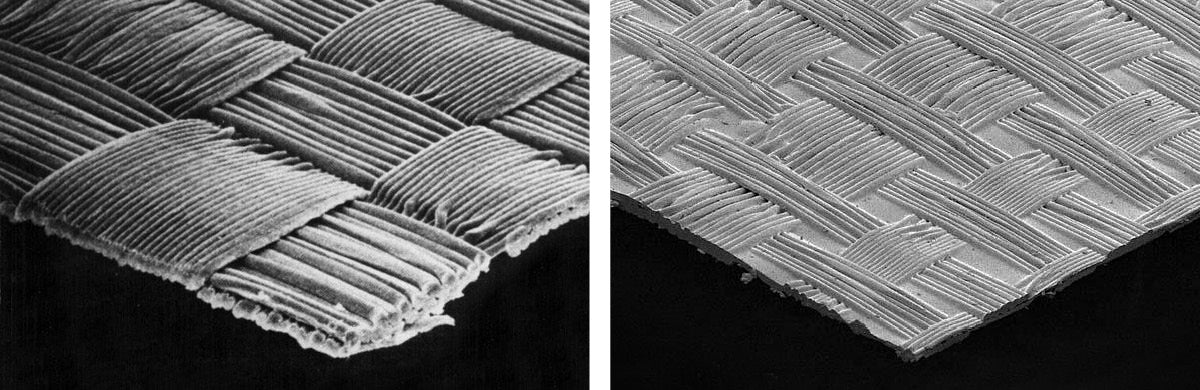

Because spinnakers operate in relatively low apparent windspeeds (wider sailing angles equal lower wind speeds felt aboard the boat), spinnaker cloth needs to be relatively light. To achieve that, nylon sailcloth is used in most spinnakers; it features small size yarns, and, in lighter-weight styles, its weave is not especially dense. Cruising-style gennakers and spinnakers are typically made from woven nylon that doesn’t push the concept of light weaving too hard. The electron microscope photo below

Porosity, which refers to the amount of air that can slip through a material, is inherently low in a spinnaker made from cloth like this. Of course, low porosity is a virtue in all sails. This is especially the case with spinnakers, which you fly when you are fighting to transmit every drop of energy from the wind to your boat. Alternatively, the cloth in hard-core racing spinnakers for light and medium windspeed ranges can weigh 40 percent less than a more cruising or crossover-style material. The photo above

It may not be a surprise to learn that the urethane-only sections of this cloth are less durable than the yarn areas. Like auto tires and plenty of other products, higher performance comes at both a reduction in durability and a higher price (coated nylon is priced higher than uncoated because it costs more to produce). If it makes you feel better, compare the price and anticipated mileage of tires for a new Porsche versus your minivan!

What are the signs of wear in spinnaker cloth?

Change in a spinnaker’s shape over time is not easy to see, especially from onboard the boat. Try to get photos from off-the-boat when your spinnaker is new to make comparisons later.

Changes you may see over time as a spinnaker ages will be subtle. You may see signs of more “corrugation” along the panel edges, especially near the corners. Vertical “elephant ass” wrinkles from the middle of the head toward the middle of the sail will become increasingly pronounced. Luff and leech panels will tend to more abruptly fold over (versus twitching) when trimming adjustments are made.

You will also find it harder to hit the numbers. Downwind sailing requires attention to target boat speed and target angle. (If you don’t know the downwind target speed and angle data for a given true windspeed for your boat, you need to get that information asap—there is a wealth of information on the web if you search “target downwind boat speed.”) If you always seem to struggle to reach these targets, your spinnaker is a likely culprit. If you used to have an extra gear when you headed up to pass a boat sitting to leeward, but that speed boost seems to be gone, your chute may be to blame.

If there has been a perceptible change in how the cloth feels (textile speak for this is the “hand” of the cloth), the sail is likely slowing down. You don’t have to work from memory for this one—drop by your sailmaker with your spinnaker and compare its material to new cloth on a roll. Be sure you are comparing the same brand and style of cloth, as there is a lot of variation in hand among different new materials.

If your spinnaker constantly ends up torn, that might be a sign of old age, too. It could also be a sign that you need to carefully check all possible contact points on your boat and rig, and get busy with tape, perhaps even a file. Spinnaker cloth will always lose to rough or burred spreader tips, broken wires on lifelines, the spinnaker pole track and car, tops of stanchions, exposed cotter pins, and bolts on hatches and companionways. Brand new spinnaker cloth is actually more prone to tear than cloth with a few hours of use, so be particularly vigilant when your sail is brand new. That being said, decades-old cloth is of course going to tear with little resistance.

If the colors of a dyed cloth spinnaker (anything other than white) are obviously faded, the sail is almost certainly on its last legs. Going back to porosity, if you can breathe any amount of air through the sail, it needs to be put out to pasture.

How to make your spinnaker last

Let’s end with a quick top five tips to get the most out of your spinnaker:

- As noted earlier, check and correct rough points on your boat where the sail can touch.

- Don’t fly your spinnaker above its recommended ranges for windspeed and angle.

- Avoid “shrimping” your spinnaker on a douse. Hauling a sail out of the water as you round a mark is really hard on the cloth.

- Minimize the time your spinnakers are wet. Never leave a wet spin in its bag until next time! Take it home or revisit the boat to get it dried out. If the sail was in salt water, rinse it with fresh water before drying it. (Dry salt crystals in spinnaker cloth act like thousands of little embedded files).

- Just in case it ever occurred to you, never put a nylon sail in a swimming pool to clean or rinse it. Chlorine is kryptonite to nylon!

Interested in a new spinnaker? Request a quote today and learn more about upgrading and filling the gaps in your downwind inventory.